Built and Shipped in 1 Day from Maysville, Kentucky

Every piece of equipment you use is critical to your business.

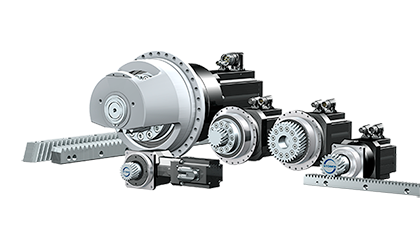

Our engineers have sized thousands of applications for customers in the most demanding sectors. From heavy-duty industrial gearboxes to motors to rack and pinion, choosing us as your motor and gearbox supplier means you have access to everything you might need.

STOBER PRODUCTS

No other servo motor company in the marketplace today has as much to offer as we do. We’re the world’s leading motor and gearbox manufacturer because the versatility of our products makes them indispensable in a vast array of industrial applications.

In addition, choosing us as your gearbox manufacturer means you benefit from our ability to design solutions for your application’s needs. The four products listed below are just a tiny fraction of everything we have to offer as your servo motor supplier. Explore our full catalog to see everything we can provide for you.

Proven Gearbox Solutions for Every Industry

STOBER is the name trusted by manufacturers across multiple industries because we understand the unique challenges they face. We adapt our products to provide peak performance and dependability in numerous industrial settings, including:

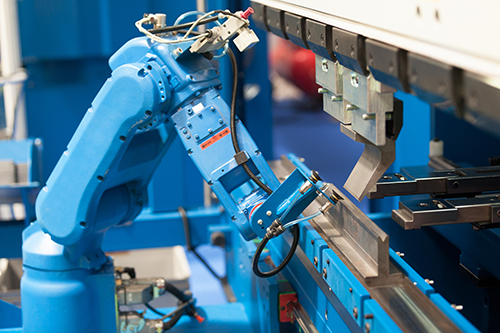

- Automation & Robotics: The gearboxes that help power automated robotic systems must deliver precision and low backlash. We support continuous, high-speed cycles with consistent accuracy.

- Food & Beverage: Gearboxes used in washdown conditions require stainless-steel housings and sealed systems to prevent contamination and corrosion. Our solutions are engineered to ensure compliance and durability in hygienic environments.

- Packaging & Material Handling: High-volume lines call for gear reducers that can withstand repetitive loads while maintaining uptime. We deliver gearboxes that support efficiency in conveyor and packaging systems.

Why Choose STOBER?

Our status as the world’s top industrial gearbox manufacturer didn’t happen overnight. We’ve been fiercely dedicated to providing the highest levels of quality and excellence since 1934. We are committed to exceeding our clients’ expectations, and we do so by offering unparalleled service support and the shortest lead times in the industry.

Working with STOBER means you can experience benefits including:

- Speed of delivery: Our industrial gearboxes are built and shipped in a single day, helping customers recover quickly from equipment failures and meet urgent production needs without much downtime.

- Extended warranty: Our industry leading -year warranties reflect the confidence we have in our products. They also provide customers with assurance of long-term performance that outpaces many of the alternatives in the industry.

- Engineering support: STOBER’s team of knowledgeable engineers brings application experience gained from thousands of projects. Their expertise helps our customers choose the right gearbox for their torque, speed, and mounting needs, reducing costly misapplications.

- Proven reliability: Our track record across automation, packaging, and food and beverage speaks for itself. STOBER’s solutions are validated in real-world environments where uptime and efficiency are crucial.

To learn more about how we can meet all your gearbox- and motor-related needs, get in touch today.

NEWS FROM STOBER

STOBER success: Boosting reliability, efficiency for a major U.S. poultry

Improve uptime and cut maintenance costs. See how STOBER cLEAN motors helped a major U.S. poultry processor save $72K with a 67‑day ROI….

Selecting gearboxes for robotic & industrial automation systems

Learn how to choose gearboxes for automation & robotics—planetary, helical, or helical-bevel—based on load, precision, environment & lifecycle cost. …

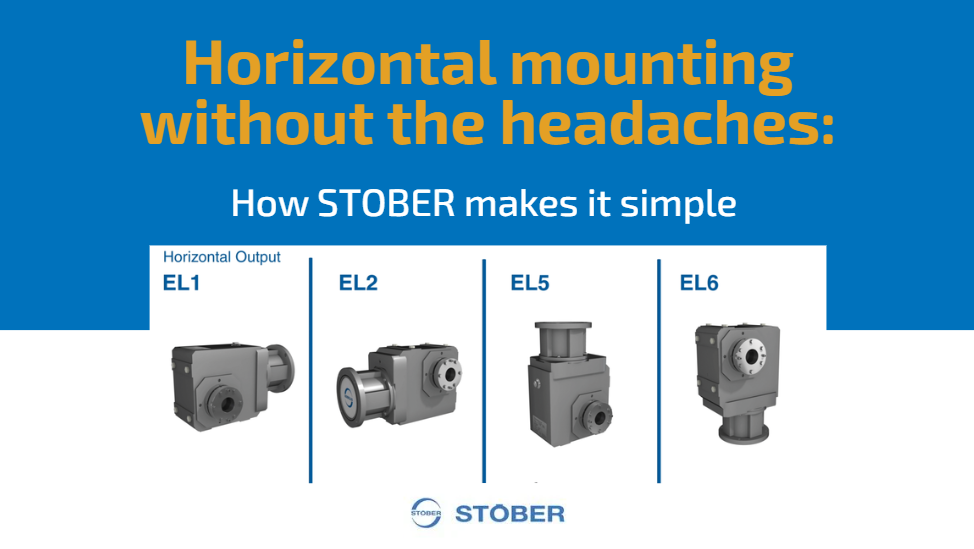

Horizontal mounting without the headaches: How STOBER makes it simple

Discover how STOBER eliminates the complexity of horizontal gearbox mounting with flexible, any‑orientation installation, reliable lubrication design, and leak‑proof seals—saving teams time, effort, and costly…

What causes gearbox failure? Key causes & early warning signs

Learn what causes failure in industrial gearboxes—lubrication breakdown, misalignment, overload, contamination & wear—plus warning signs to catch early….