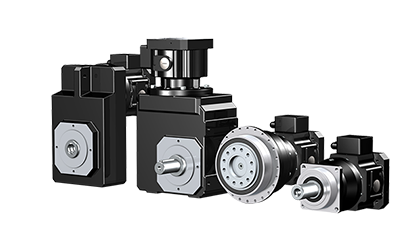

Inline Gearboxes: Helical & Planetary

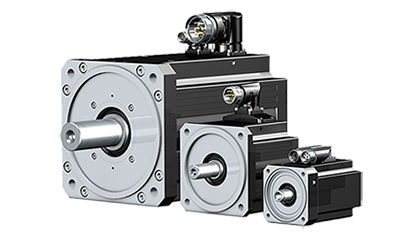

STOBER inline servo gearboxes are unrivaled in their precision and options. Choose from planetary gearing or take advantage of helical gearing. Servo doesn’t have to mean planetary! These inline helical gearboxes and inline planetary gearboxes can be mounted to any motor with our toleranced motor adapters, or you can add a STOBER motor to them to make a geared motor. These industrial gearboxes are assembled in our Maysville, Kentucky facility, shipped in one day, and come with a five-year warranty.

Whether you need high-precision planetary inline gearboxes for demanding servo applications or quiet, efficient helical inline gearboxes for general automation, STOBER offers flexible, modular solutions engineered for durability and easy integration. Our inline servo gearboxes support a wide range of torque requirements, gear ratios, and mounting options to fit diverse industrial automation needs, from robotics and packaging to material handling and machine tools. With advanced engineering, low backlash, and robust motor adapters, STOBER gearboxes deliver smooth power transmission and consistent performance in even the most challenging environments.

The P series of custom inline gearbox solutions features planetary gearing, providing unsurpassed smoothness and precision.

It is incredibly efficient, has low backlash, and runs quiet.

Plus, you can choose from several bearing options to handle radial or axial loads, optimizing your machine design.

P planetary gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

P Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 3 – 100

- Acceleration torque: 11 – 3,450 Nm

- Nominal torque: 16 – 2,483 Nm

- Continuous Input Speed: Up to 6,000 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 407 Nm/arcmin

P Series: FEATURES

- Output Shaft:

- Plain shaft

- Feather key

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Double row angular contact bearing – ideal for high axial loads

- Cylindrical roller bearing – ideal for radial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Food Duty - 316 stainless steel epoxy paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Motor Adapter:

- ME – standard clamp coupling

- Seal option - MSS1 seal for longer life

- MEL - clamp coupling that can accommodate larger diameter motor shaft without upsizing to larger gearbox

- MF - flexible coupling, ideal for thermal length compensation

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Available as a geared motor!

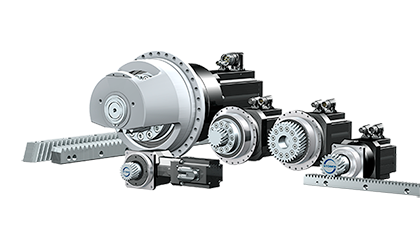

- Available as a rack and pinion system

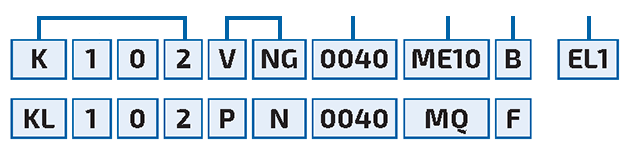

P Series: PART NUMBER EXAMPLE:

The C series utilizes helical gears for up to 97% efficiency.

Choose the housing style that fits your application – round or square flanges, tapped holes, or foot mounting.

C helical gearboxes are available as compact inline servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

C Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 2 – 276

- Acceleration torque: 36 – 8,000 Nm

- Nominal torque: 35 – 7,000 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 393 Nm/arcmin

C Series: FEATURES

- Housing Styles:

- Round output flange

- Pitch circle diameter tapped holes

- Foot mounting

- Square output flange

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty - 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty - 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Motor Adapter:

- ME – standard clamp coupling

- Seal option - MSS1 seal for longer life

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Available as a geared motor!

C Series: PART NUMBER EXAMPLE:

The PH series inline gear systems offers superior stiffness and accuracy.

These inline planetary gearboxes offers a reinforced bearing option for applications with higher axial loads.

PH gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

PH Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 4 – 121

- Acceleration torque: 60 – 7,500 Nm

- Nominal torque: 36 – 5,000 Nm

- Continuous Input Speed: Up to 6,000 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 1,743 Nm/arcmin

PH Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Coating Options: options for different environments.

- Standard - RAL-9005 black paint

- Washdown - 316 stainless steel epoxy paint

- Motor Adapter:

- ME – standard clamp coupling

- Seal option - MSS1 seal for longer life

- MF - flexible coupling, ideal for thermal length compensation

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Available as a geared motor!

- Available as a rack and pinion system

PH Series: PART NUMBER EXAMPLE:

The PE series is an attractive option for applications that don’t require the highest precision or smoothness.

It's unique for an economy option because it utilizes helical gearing.

PE gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

PE Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 3 – 100

- Acceleration torque: 13 – 310 Nm

- Nominal torque: 7 – 160 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 35 Nm/arcmin

PE Series: FEATURES

- Coating Options: options for different environments.

- Standard - RAL-9005 black paint

- Washdown - 316 stainless steel epoxy paint

- Motor Adapter:

- ME – standard clamp coupling

- MEL - clamp coupling that can accommodate larger diameter motor shaft without upsizing to larger gearbox

- Available as a geared motor!

- Available as a rack and pinion system

PE Series: PART NUMBER EXAMPLE:

The PHQ series features four planetary gears, making it the most powerful gearbox on the market.

It provides smooth operation while producing huge amounts of torque.

PHQ gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

PHQ Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 5.5 – 600

- Acceleration torque: 200 – 43,000 Nm

- Nominal torque: 100 – 25,000 Nm

- Continuous Input Speed: Up to 4,500 RPM

- Cyclic Input Speed: Up to 8,000 RPM

- Torsional Stiffness: Up to 6,269Nm/arcmin

PHQ Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Coating Options: options for different environments.

- Standard - RAL-9005 black paint

- Washdown - 316 stainless steel epoxy paint

- Motor Adapter:

- ME – standard clamp coupling

- Seal option - MSS1 seal for longer life

- MF - flexible coupling, ideal for thermal length compensation

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Available as a geared motor!

- Available as a rack and pinion system

PHQ Series: PART NUMBER EXAMPLE:

| Title | Version | ID | Date | Size | ||

|---|---|---|---|---|---|---|

| Servo Gearboxes | 33 | 442934 | 2024 06 | EN | 38.02 MB |