Created to provide a long-lasting system that improves your plant’s reliability, STOBER’s cLEAN System is durable, efficient, and guaranteed to work in the harshest environments–it’s the world’s toughest system.

Created to provide a long-lasting system that improves your plant’s reliability, STOBER’s cLEAN System is durable, efficient, and guaranteed to work in the harshest environments–it’s the world’s toughest system.

The Burke antimicrobial clear top coat featured on STOBER’s food-duty packaged products is proven to eliminate the spread of dangerous pathogens and infectious bacterial growth against more than 600 bacteria including legionella, salmonella, e-coli, staph, and more.

The new STOBER cLEAN System is hygienically designed, making it the ultimate solution for food processing.

The STOBER cLEAN System was named “Best of the Best” recipient at the 2025 International Production & Processing Expo (IPPE).

Did you know that the world’s toughest gearbox doesn’t require oil changes? STOBER’s KSS stainless steel, K, C, and F series reducers (in food-duty or corrosion-resistant options) require no maintenance due to efficient gearing, housing design, quality components, and expert assembly.

STOBER’s cLEAN Drive is designed for optimal control of the cLEAN Motor using a permanent magnet sensorless vector control. Easy to install and program, the cLEAN Drive comes with basic motor parameters already written on the drive.

We hope our blog has been informative, useful, and inspiring this year. As a review of 2024, we look back at some of the year’s top blog posts and recap them here. Feel free to browse them again, or check them out if you missed them!

Let’s explore the different types of magnetic fields used in motors, the principles of induction motors, and the innovative permanent magnet technology featured in STOBER’s cLEAN motor.

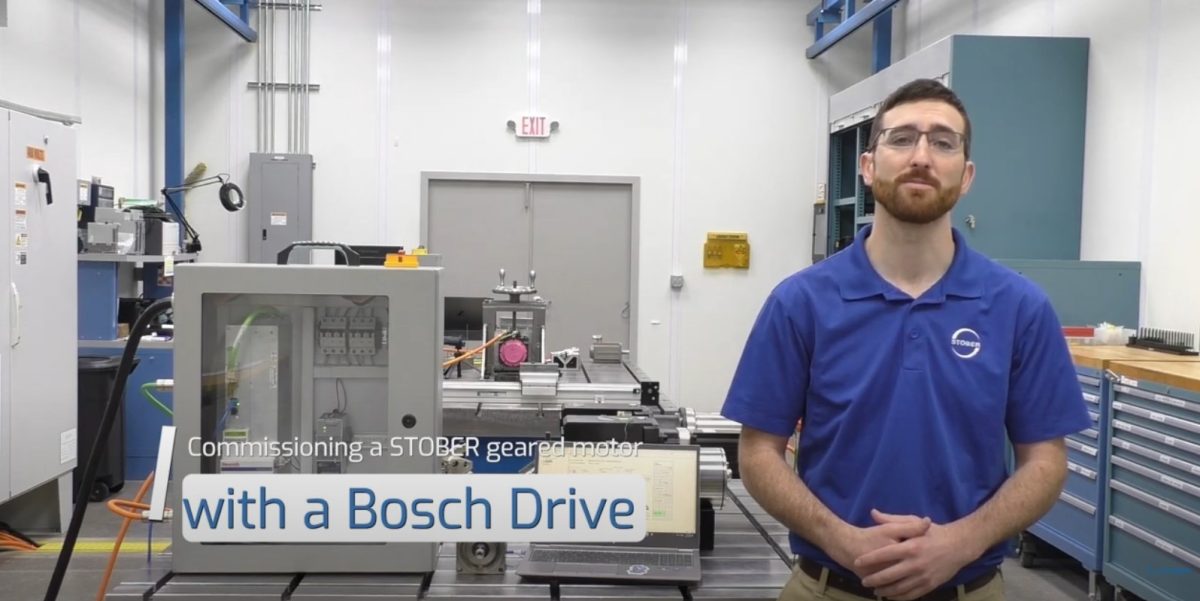

Commissioning a STOBER geared motor with a Bosch drive is easier than you may think. Watch the video for step-by-step instructions.

STOBER has made it even easier for factories to maximize productivity and eliminate unplanned downtime with the cLEAN System. STOBER’s cLEAN System eliminates premature failure due to water ingress, has IE5 energy efficiency, and is designed to EHEDG standards.