IP69K rating has two elements of testing: level of protection against solid matter such as dust, and level of protection against water ingress. The passing criterion for each is no ingress of foreign particles or liquids inside the gearbox or motor.

IP69K rating has two elements of testing: level of protection against solid matter such as dust, and level of protection against water ingress. The passing criterion for each is no ingress of foreign particles or liquids inside the gearbox or motor.

Maysville Community & Technical College (MCTC) recently honored STOBER General Manager Peter Feil for his service to their Board of Directors. Feil said he is very grateful for having had the opportunity to serve on the MCTC Board.

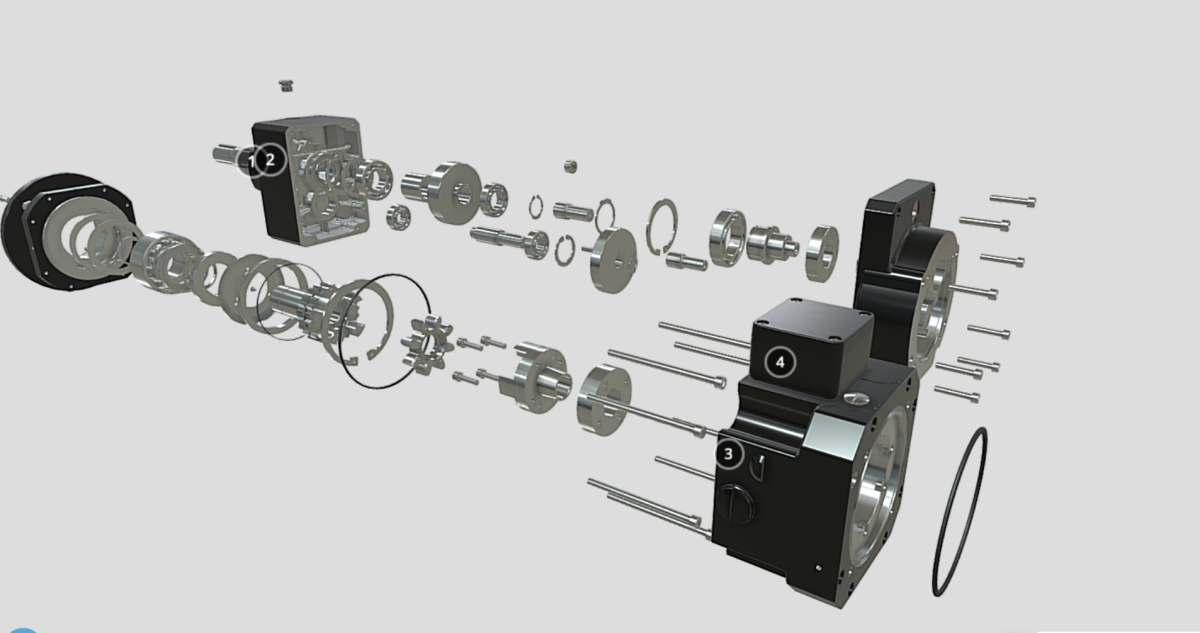

If you’re curious about STOBER’s ServoStop integrated safety brake for servo gearboxes, you’re in luck—3D models of the product are now available on the STOBER website!

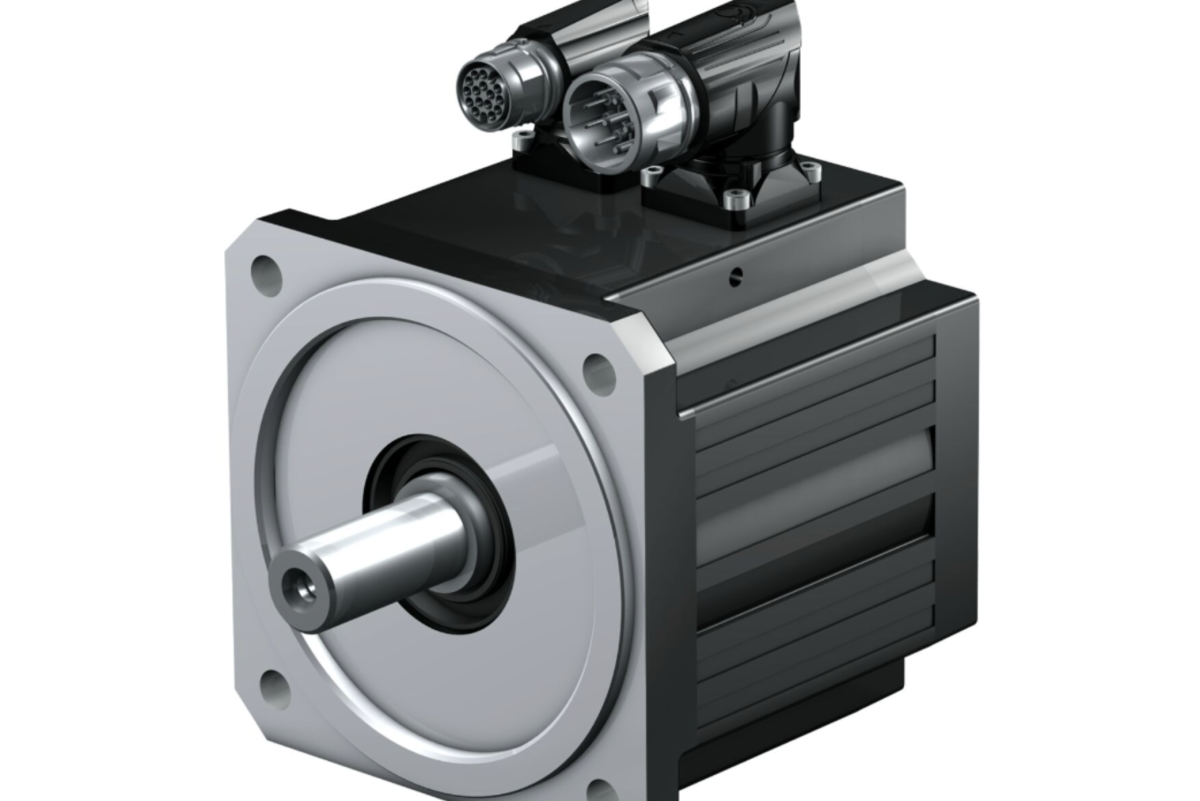

STOBER motors and geared motors are flexible in design and compatibility with third-party drives.

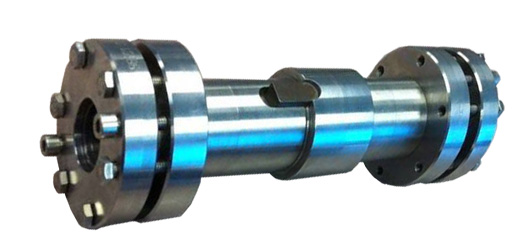

STOBER’s wobble-free bushing is a patented double side bushing system that mounts onto standard cold finished, ground, or stainless shafts.

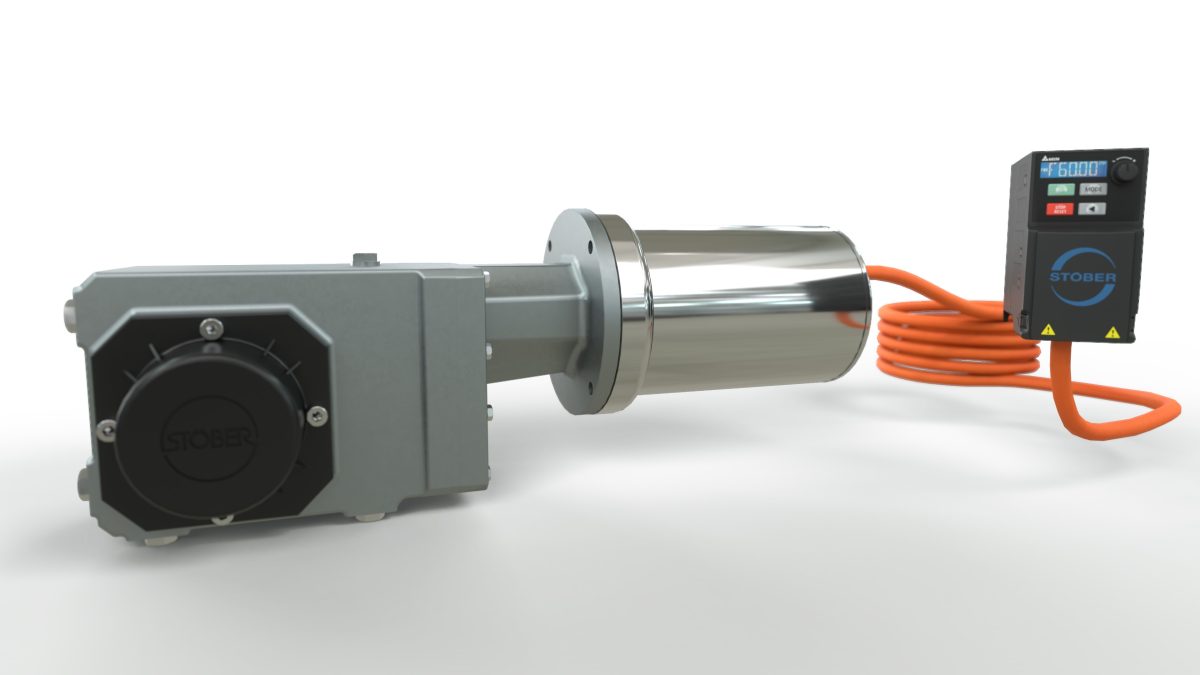

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s reliability. Durable, efficient, and guaranteed to work in the harshest environments.

Are you frustrated with lead times for motors? STOBER has several options readily available from Maysville, Ky. Our Kentucky facility stocks the EZ3 (72mm frame size), EZ4 (98mm), EZ5 (115mm), and EZ7 (145mm) motors.*

Did you know STOBER’s synchronous servo geared motors are a packaged solution? Yep, you can be back up and running faster than ever because with STOBER’s packaged solution, installation is easy.