STOBER’s commitment to clear and consistent communication provides peace of mind that comes with seamless collaboration and transparent updates, allowing OEMs to focus on core business objectives while STOBER handles the details.

STOBER’s commitment to clear and consistent communication provides peace of mind that comes with seamless collaboration and transparent updates, allowing OEMs to focus on core business objectives while STOBER handles the details.

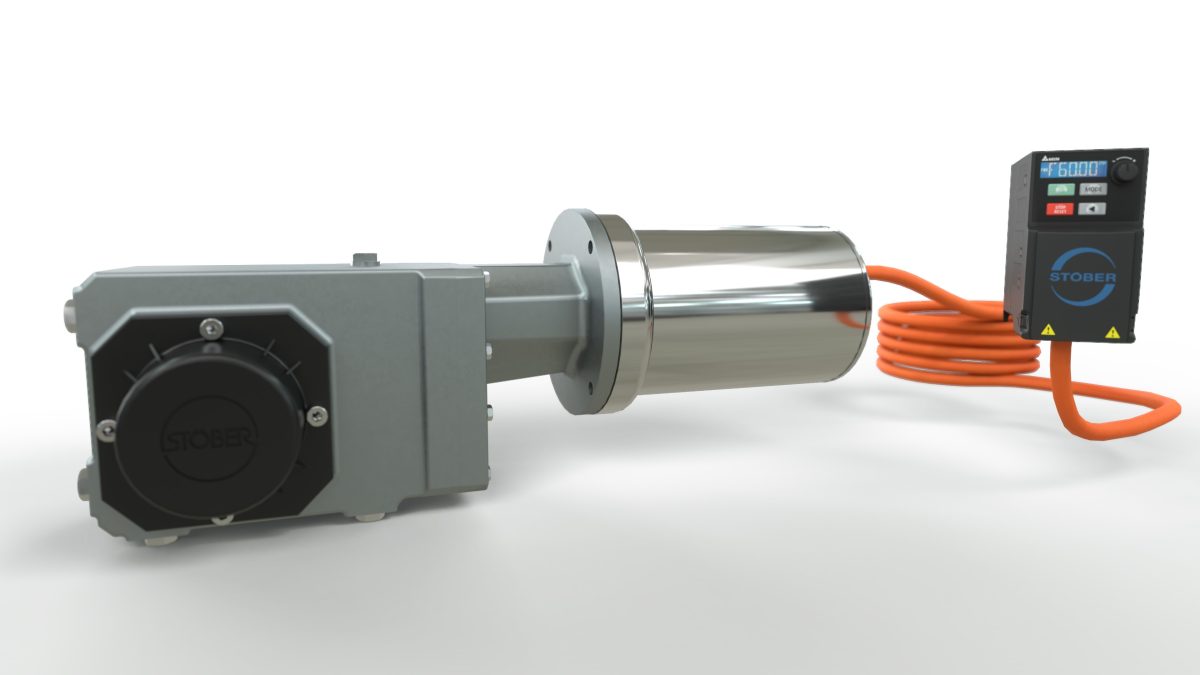

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s reliability. Durable, efficient, and guaranteed to work in the harshest environments.

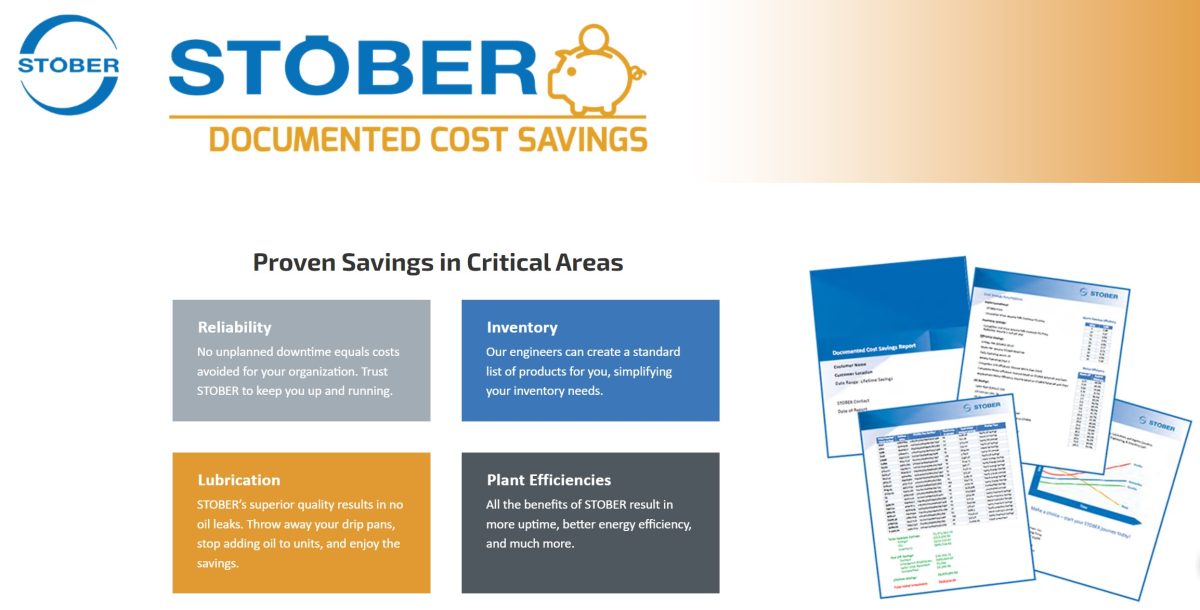

It’s well known that STOBER products last longer, require less maintenance, use less energy, and optimize the plant floor. But don’t just take our word for it–use our Documented Cost Savings tool to calculate just how much your company could save by using STOBER.

The STOBER KSS gearbox and cLEAN Motor recently received IP68 certification in addition to the already-existing IP69K certification, IE5 energy efficiency, and design to EHEDG standards.

Don’t get stuck in a solution—find the best fit! STOBER’s inline planetary geared motor solution takes up less space in your machine footprint than a right-angle planetary solution.

The STOBER team takes a hands-on approach to help maintenance crews learn to install STOBER equipment on their food production lines.

STOBER’s stainless steel & food-duty gearboxes can handle the harshest washdowns and withstand the acidic nature of cheese.

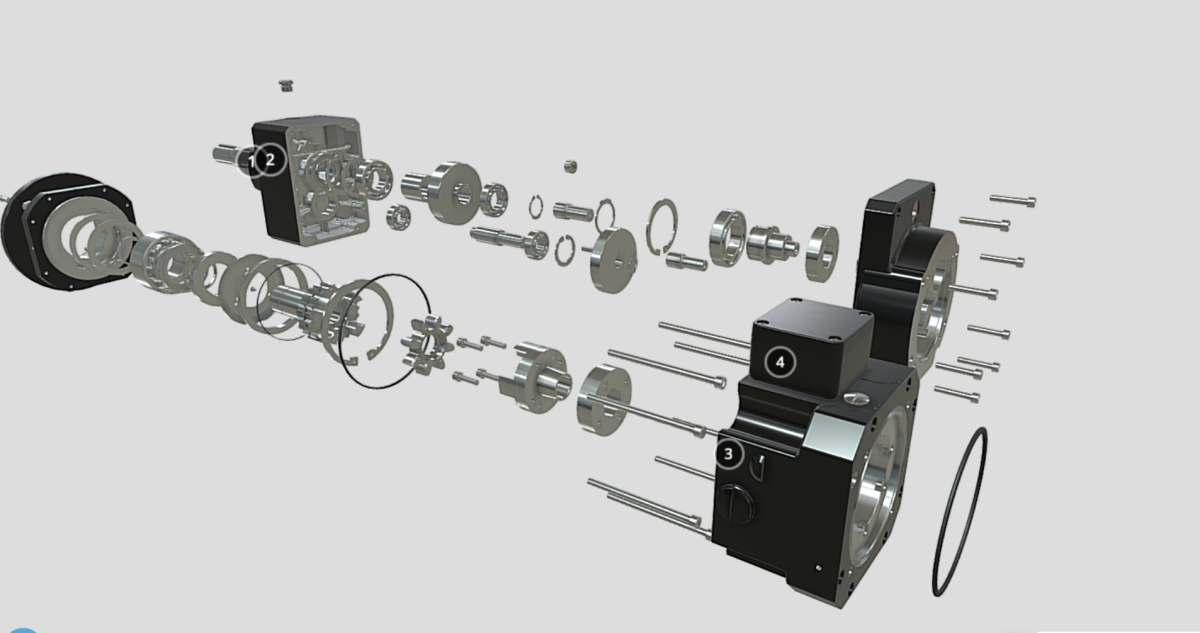

The most compact planetary geared motors on the market just got better. Now with a space-saving design, STOBER’s PH9-12 Generation 4 products feature lower weight, lower mass inertia, higher rigidity, and up to 20 percent more torque. Plus, the reducer interface is 100 percent compatible to the previous generation!

STOBER is proud to work with Millard for meat processing equipment that provides sanitary design, equipment reliability, food safety, and more.

If you’re curious about STOBER’s ServoStop integrated safety brake for servo gearboxes, you’re in luck—3D models of the product are now available on the STOBER website!