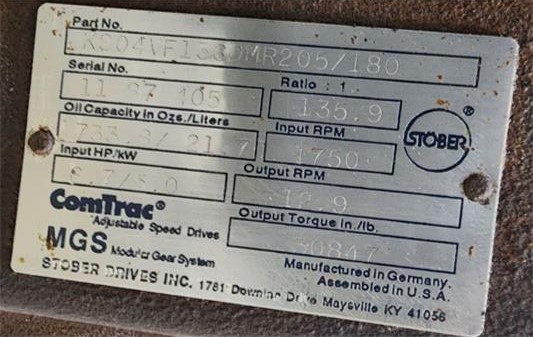

In 1997, a snack food manufacturer installed a STOBER K8 gearbox in their facility. The particular gearbox broke down recently, after 27 years of life.

In 1997, a snack food manufacturer installed a STOBER K8 gearbox in their facility. The particular gearbox broke down recently, after 27 years of life.

Congratulations to STOBER Drives’ newest class of apprentices who recently signed to continue their employment and education.

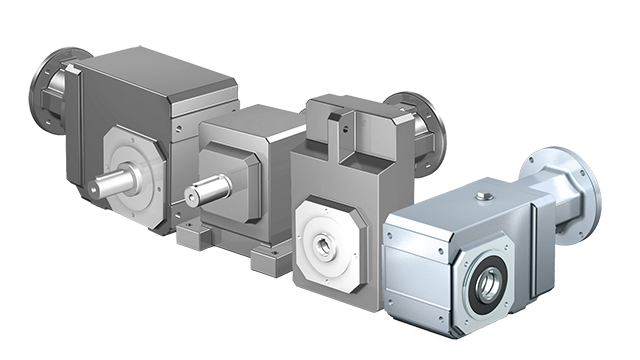

Don’t get stuck in a solution—find the best fit! STOBER’s inline planetary geared motor solution takes up less space in your machine footprint than a right-angle planetary solution.

In memory of Mike Noel and Logan Cooper, STOBER is hosting a golf scramble at Kenton Station Golf Course on Saturday, May 18. All proceeds from the event go toward a scholarship fund for Mike’s grandson and Logan’s two sons.

Billie Wallingford, a machinist on our manufacturing team, has worked at STOBER for more than 10 years and will be retiring on April 26.

STOBER’s stainless steel & food-duty gearboxes can handle the harshest washdowns and withstand the acidic nature of cheese.

The most compact planetary geared motors on the market just got better. Now with a space-saving design, STOBER’s PH9-12 Generation 4 products feature lower weight, lower mass inertia, higher rigidity, and up to 20 percent more torque. Plus, the reducer interface is 100 percent compatible to the previous generation!

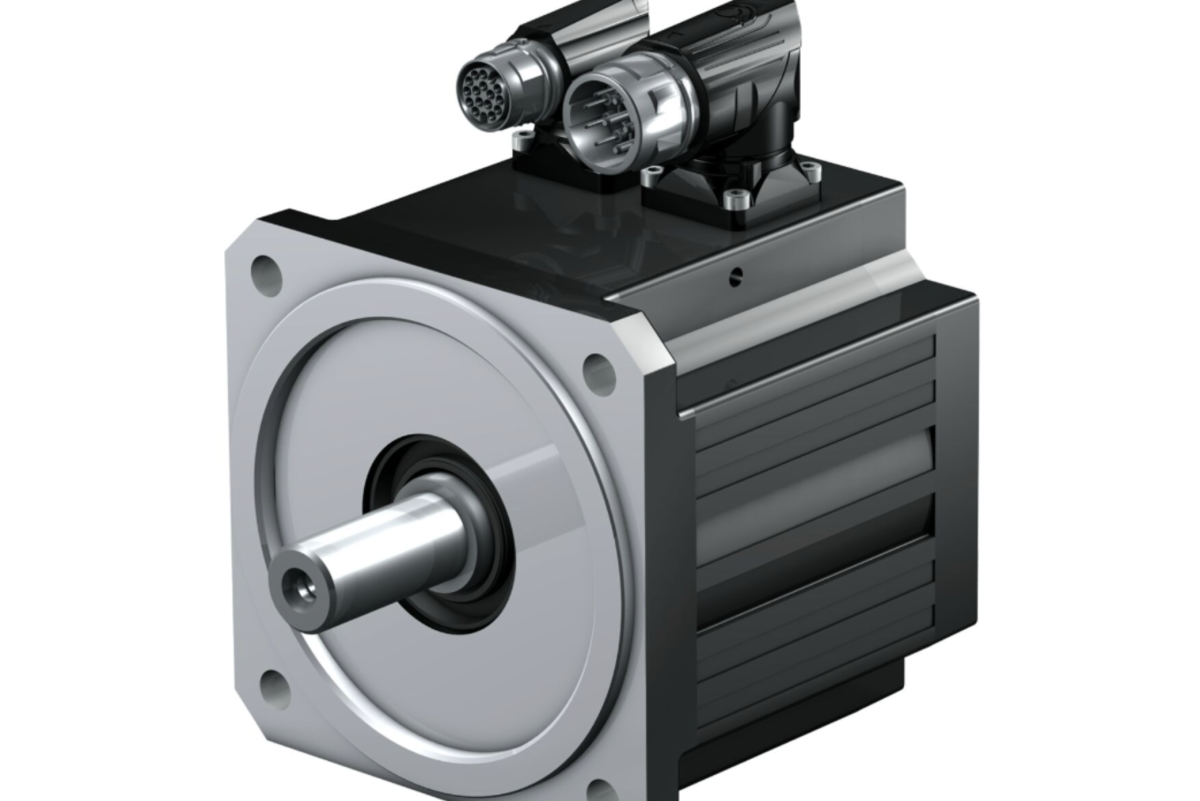

Are you frustrated with lead times for motors? STOBER has several options readily available from Maysville, Ky. Our Kentucky facility stocks the EZ3 (72mm frame size), EZ4 (98mm), EZ5 (115mm), and EZ7 (145mm) motors.*