With a variety of gearboxes on the market that can fulfill diverse requirements, selecting the best power transmission gearbox can be a challenge. Avoid making a wrong decision to avoid wasting money on a more expensive gearbox that isn’t necessary.

With a variety of gearboxes on the market that can fulfill diverse requirements, selecting the best power transmission gearbox can be a challenge. Avoid making a wrong decision to avoid wasting money on a more expensive gearbox that isn’t necessary.

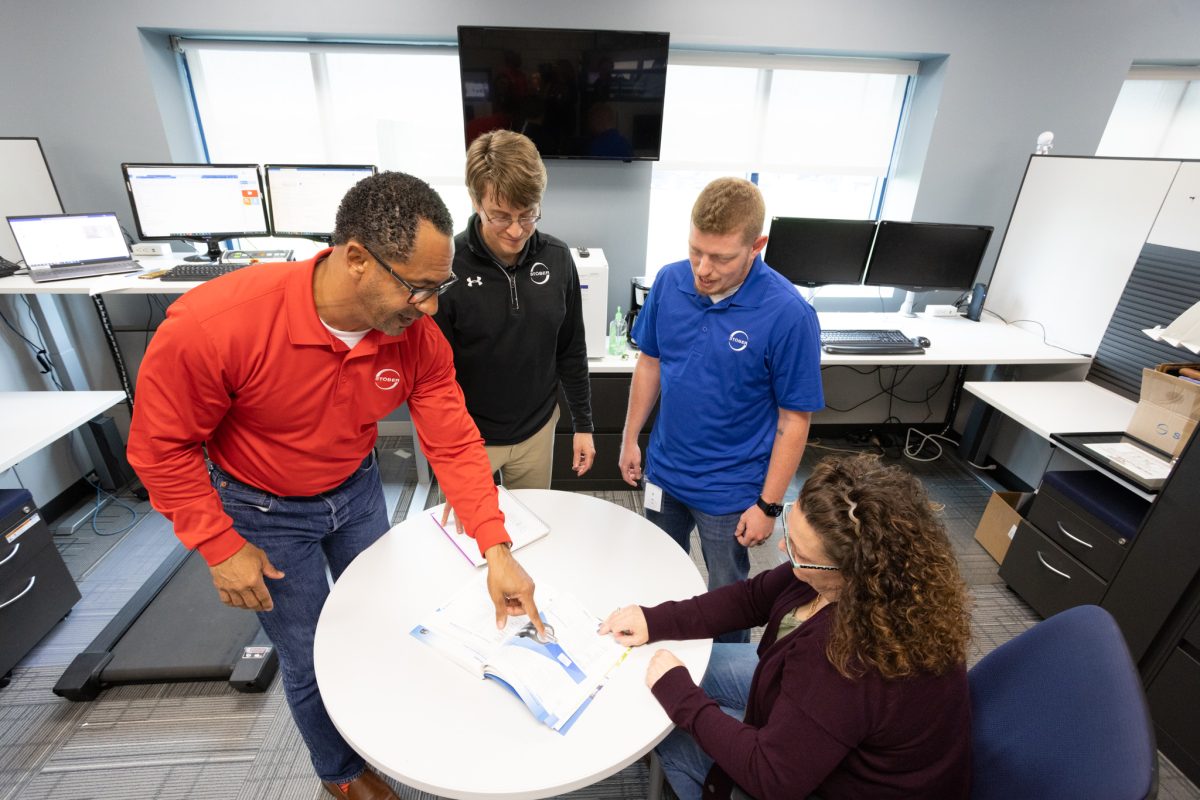

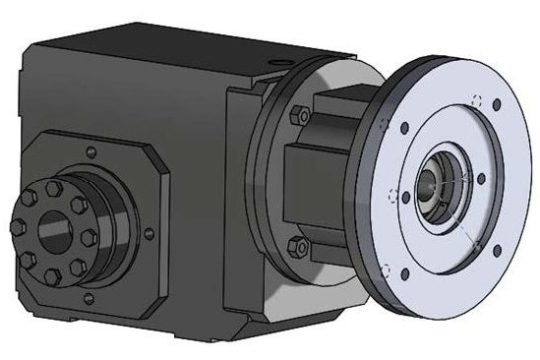

As a consumer, you use 3D modeling when you research items such as cars, clothing, shoes, and appliances online, so why shouldn’t you see 3D models of your gearboxes too? Now you can with STOBER’s new 3D modeling tools.

If you have questions about our products you’d like answered, a tough application you need a solution for, or just want to touch base and put a name with a face, us our Meeting Request tool to schedule some one-on-one time with our team!

Join us at Maysville Oktoberfest on Saturday, Aug. 12 from 4 p.m. to 6 p.m. and find out at the STOBER Stein Dash!

At STOBER, we’re proud to build and ship in only one day from our facility in Maysville, Kentucky, so our customers don’t have to worry about lead times.

STOBER’s NEMA right-angle gearboxes are ideal to keeping downtime minimized in the beverage industry.

STOBER servo geared motors consist of a gearbox assembled onto the motor for a lighter, more compact solution with less maintenance.

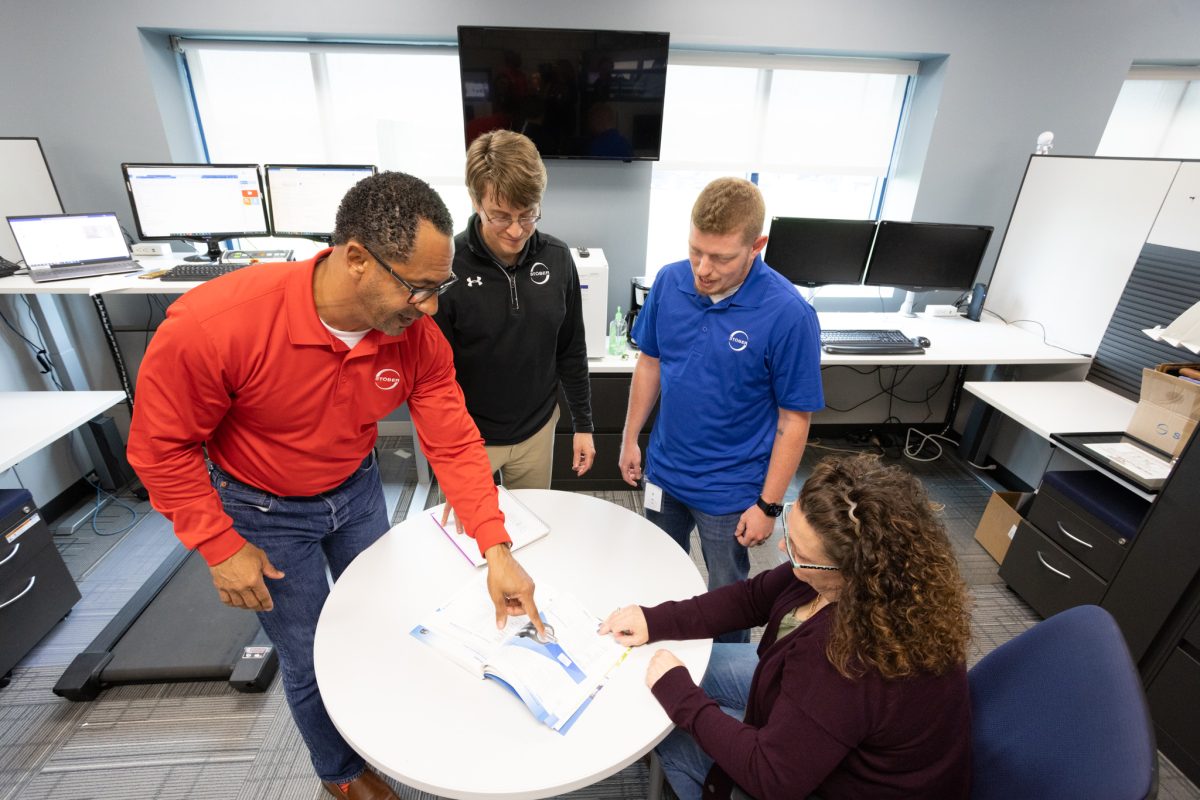

STOBER engineers recently completed training for motors and controls through hands-on learning experiences at the historic Cox Building in downtown Maysville.

When it comes to using a hydraulic motor adapter with a STOBER gearbox, it has never been easier!

Best practices when installing and connecting cables in a manufacturing environment ensures safety and extends equipment life.