The STOBER cLEAN System was named “Best of the Best” recipient at the 2025 International Production & Processing Expo (IPPE).

The STOBER cLEAN System was named “Best of the Best” recipient at the 2025 International Production & Processing Expo (IPPE).

STOBER’s cLEAN Drive is designed for optimal control of the cLEAN Motor using a permanent magnet sensorless vector control. Easy to install and program, the cLEAN Drive comes with basic motor parameters already written on the drive.

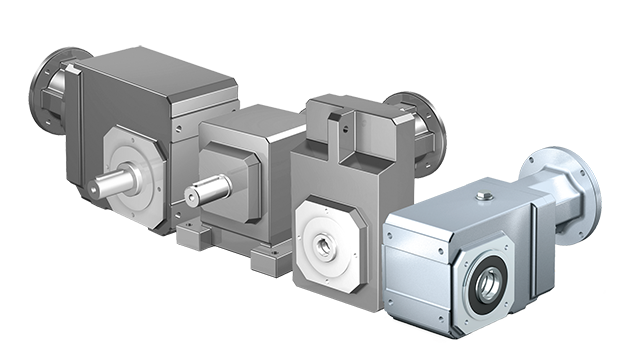

Designed to provide the highest degree of resiliency and durability, STOBER’s NEMA gearboxes deliver superior performance that can revolutionize how well equipment functions across numerous processes and industries.

We hope our blog has been informative, useful, and inspiring this year. As a review of 2024, we look back at some of the year’s top blog posts and recap them here. Feel free to browse them again, or check them out if you missed them!

Let’s explore the different types of magnetic fields used in motors, the principles of induction motors, and the innovative permanent magnet technology featured in STOBER’s cLEAN motor.

While rack and pinion products are not new for STOBER, the new ZS Rack elevates STOBER’s rack and pinion offerings.

STOBER Drives has recently adapted an Apprenticeship 2.0 program, an expansion of the company’s apprenticeship program that began in 2006.

Representatives from STOBER recently attended Women in Manufacturing events hosted by Maysville Community and Technical College.

Commissioning a STOBER geared motor with a Bosch drive is easier than you may think. Watch the video for step-by-step instructions.