Congratulations to STOBER Drives’ newest class of apprentices who recently signed to continue their employment and education.

Congratulations to STOBER Drives’ newest class of apprentices who recently signed to continue their employment and education.

The STOBER team takes a hands-on approach to help maintenance crews learn to install STOBER equipment on their food production lines.

STOBER’s stainless steel & food-duty gearboxes can handle the harshest washdowns and withstand the acidic nature of cheese.

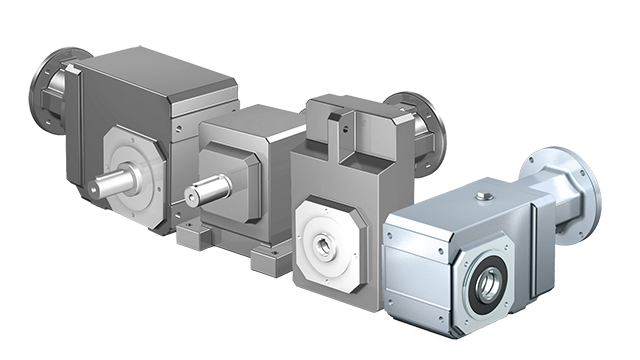

The most compact planetary geared motors on the market just got better. Now with a space-saving design, STOBER’s PH9-12 Generation 4 products feature lower weight, lower mass inertia, higher rigidity, and up to 20 percent more torque. Plus, the reducer interface is 100 percent compatible to the previous generation!

STOBER is proud to work with Millard for meat processing equipment that provides sanitary design, equipment reliability, food safety, and more.

IP69K rating has two elements of testing: level of protection against solid matter such as dust, and level of protection against water ingress. The passing criterion for each is no ingress of foreign particles or liquids inside the gearbox or motor.

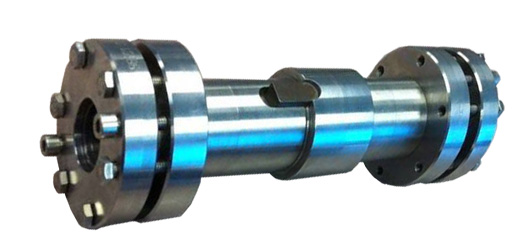

STOBER’s wobble-free bushing is a patented double side bushing system that mounts onto standard cold finished, ground, or stainless shafts.

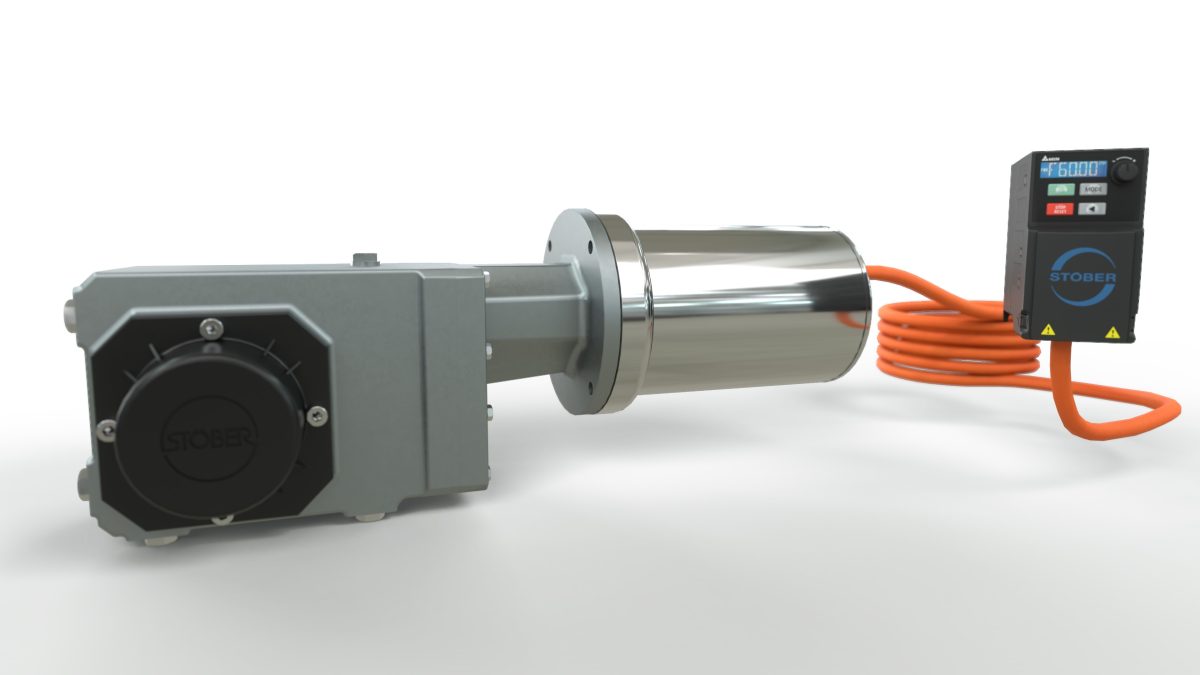

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s reliability. Durable, efficient, and guaranteed to work in the harshest environments.