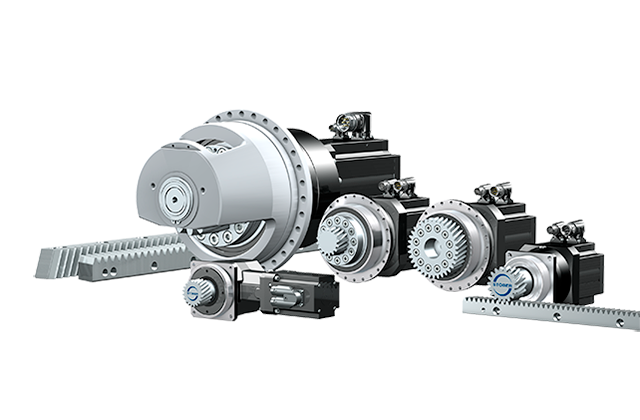

Inline geared motors, right angle geared motors, geared motors with rack and pinion, geared motors with fans, geared motors with brakes – STOBER has the range you need for your application.

- Tags america, clean motor, clean system, Company, compatibility, customer service, delivery, drive, food industry, food manufacturing, food processing, frame size for motor, gear units, gearbox, geared, geared motor, geared motors, geared motors with fans, harsh washdown, helical, hygienic, hygienic washdown, inline motor, IP68, IP68 certification, IP68 Certified, ip69k, IP69K Certified, Kentucky, kss, KSS gearbox, lubrication, manufacturing, maysville, mechatronics, motor frame sizes, motors, packaging, planetary, poultry processing, power transmission, Rack & pinion, rack and pinion, rack and pinion motor, right angle geared motor, right angle motor, servo, servo motors, servostop, stainless steel, STOBER, stober drives, the clean system, united states, warranty, washdown