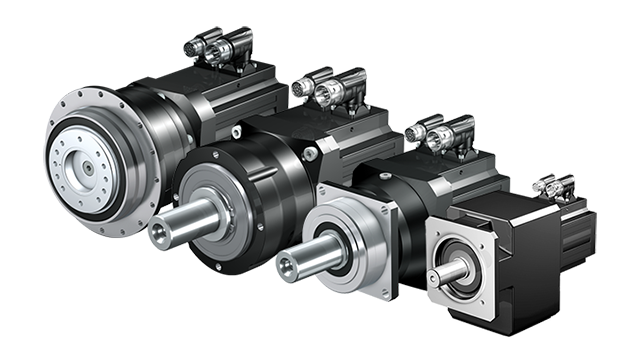

Explore the main types of geared motors, including planetary, helical, worm & right-angle designs, and learn how each supports precision, torque, & efficiency.

- Tags accuracy, america, assembly, automotive, bearing, blog, Careers, compatibility, configurator, configure, connection, cost savings, customer service, delivery, documentation, drive, efficiency, endat, fast delivery, food & beverage, food and beverage, food manufacturing, food processing, food production, gear, gear reducer, gear reduction, gear unit, gear units, gearbox, gearbox maintenance, geared, geared motor, geared motors, harsh washdown, helical, helical bevel, helical gearbox, hygiene, hygienic, industrial gearbox, inline helical, IPPE, Kentucky, lubrication, machine tool, machining, manufacturing, material handling, maysville, mechatronics, motion control, motor, motors, mounting options, no oil changes, OEM, oem renewal, oil, oil change, packaging, paint, permanent magnet, planetary, planetary gearbox, power transmission, precision, premature failure, printing, Rack & pinion, rack and pinion, reduced backlash, reduction, relationship, reliability, repair, service, servo, servo motor, servo motors, shaft, software, stainless steel, STOBER, stober drives, success, supply chain, three-year warranty, tools, torque, united states, warranty, washdown