STOBER Drives has named Rypli Donahue, Brenna Harris, and Taylor Watts winners of the 2024 Ashley Hurst, Ray Williams and Mike Noel Memorial Scholarship.

STOBER Drives has named Rypli Donahue, Brenna Harris, and Taylor Watts winners of the 2024 Ashley Hurst, Ray Williams and Mike Noel Memorial Scholarship.

STOBER is proud to work with Millard for meat processing equipment that provides sanitary design, equipment reliability, food safety, and more.

STOBER is proud to be a member of the Rockwell Automation PartnerNetwork as part of an integrated team of engineering specialists and suppliers.

IP69K rating has two elements of testing: level of protection against solid matter such as dust, and level of protection against water ingress. The passing criterion for each is no ingress of foreign particles or liquids inside the gearbox or motor.

Maysville Community & Technical College (MCTC) recently honored STOBER General Manager Peter Feil for his service to their Board of Directors. Feil said he is very grateful for having had the opportunity to serve on the MCTC Board.

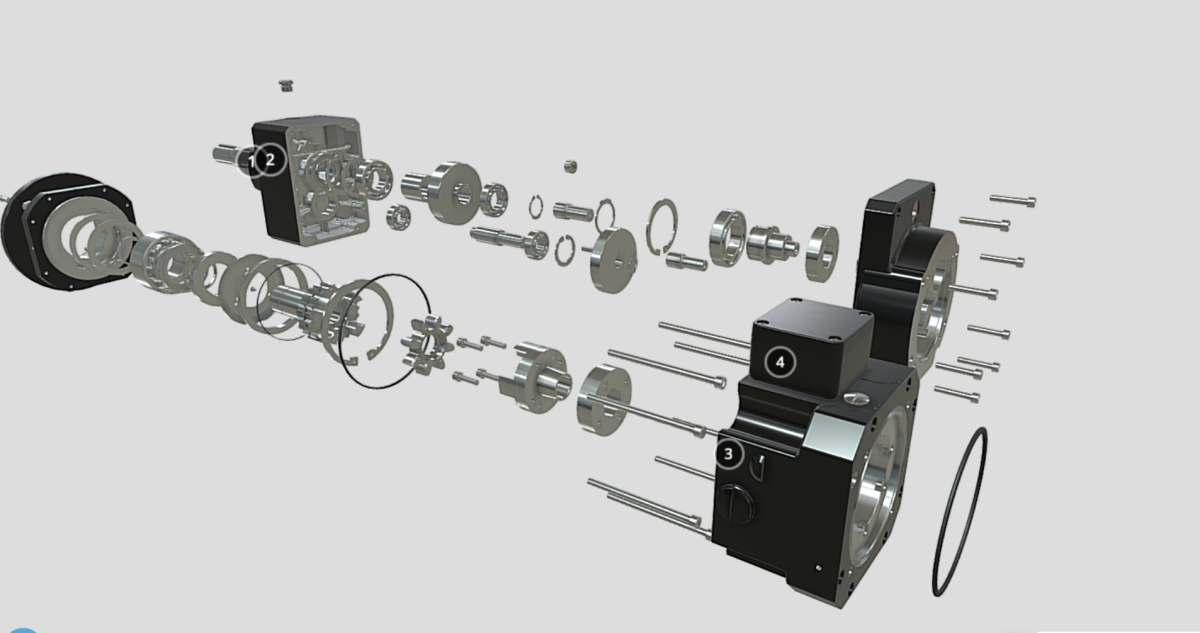

If you’re curious about STOBER’s ServoStop integrated safety brake for servo gearboxes, you’re in luck—3D models of the product are now available on the STOBER website!

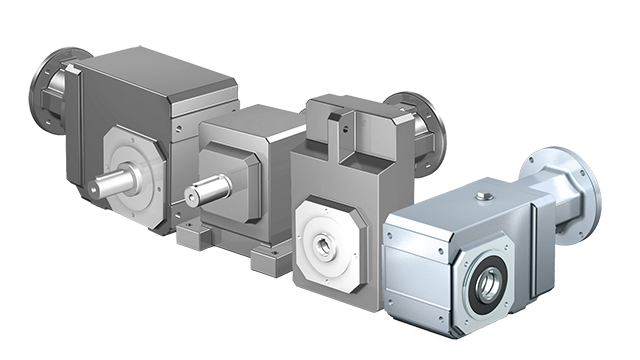

STOBER motors and geared motors are flexible in design and compatibility with third-party drives.

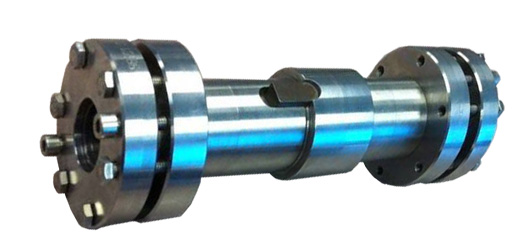

STOBER’s wobble-free bushing is a patented double side bushing system that mounts onto standard cold finished, ground, or stainless shafts.