When an assembly line needs to stop immediately due to a hazardous situation, you need STOBER ServoSoft designed for redundant braking power.

When an assembly line needs to stop immediately due to a hazardous situation, you need STOBER ServoSoft designed for redundant braking power.

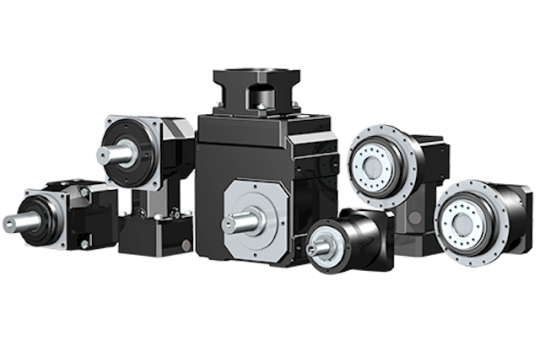

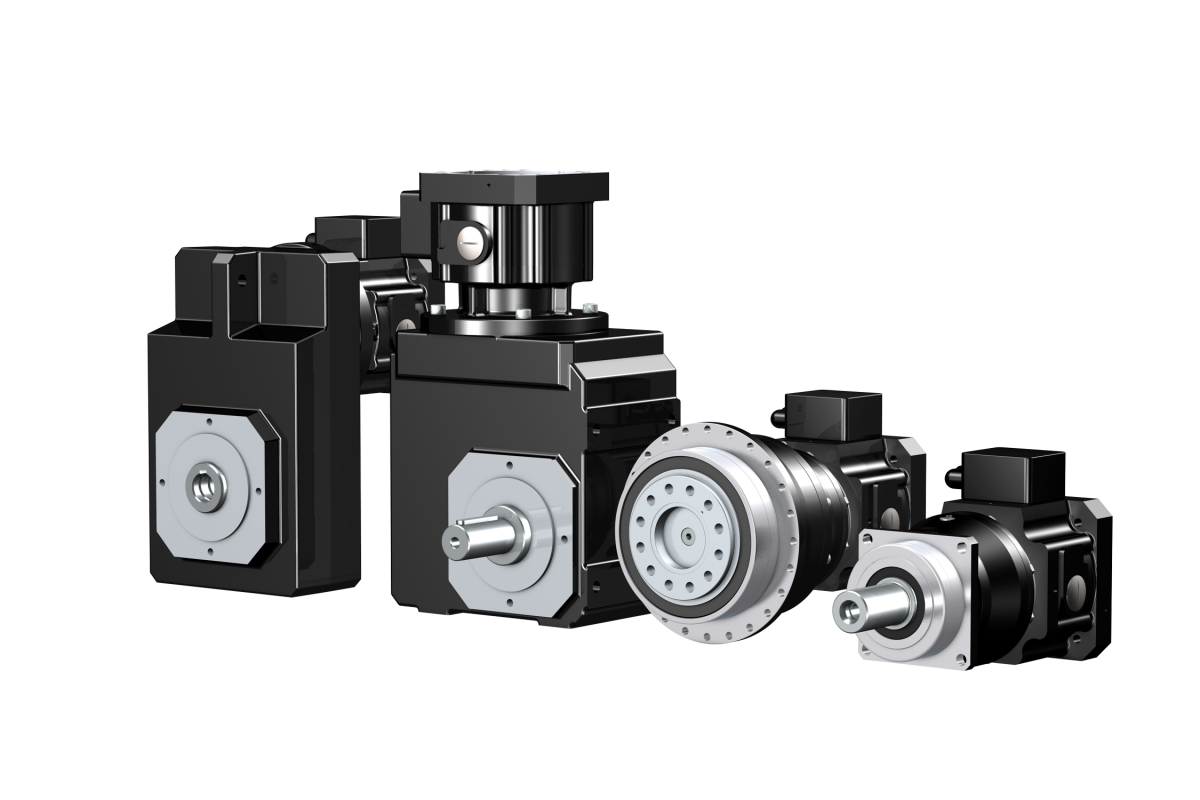

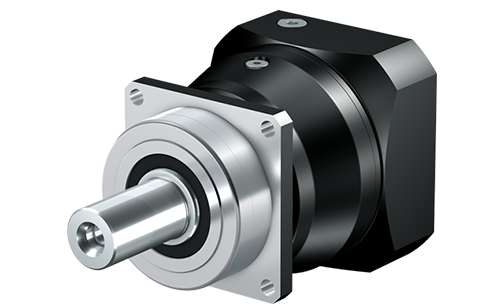

STOBER’s servo gearboxes outperform the competition when it comes to performance, backlash, running temperature, and compatibility.

STOBER will host an open house for interested high school juniors and seniors on April 12, 2023.

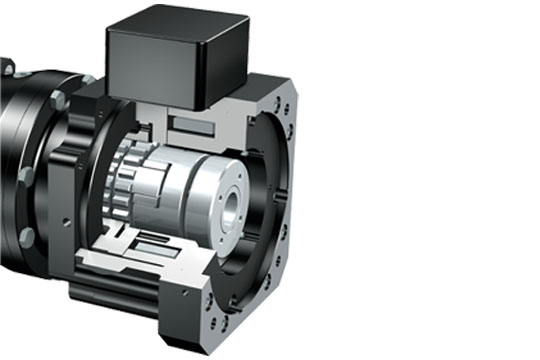

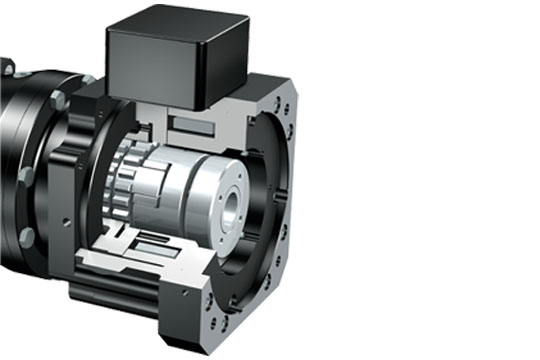

Did you know STOBER’s servo gearboxes can be paired with ServoStop, a revolutionary integrated safety brake? It’s ideal for vertical applications, provides redundant braking, and prevents slipping or falls even when the motor is removed.

STOBER gearboxes are the least expensive you’ll ever own. From no maintenance to storeroom optimization to energy efficiency and more, let us show you how we can save you money.

Gearbox oil leaks can be a maintenance nightmare – especially in food or beverage applications. STOBER knows differences matter, which is why we evaluate our lubrication thoroughly.

STOBER offers several free tools and software to help implement the best mechatronic solution for your application.

STOBER’s planetary series allows you to choose from several bearing options to handle radial or axial loads, optimizing your machine design.

STOBER Drives, Inc. is proud to announce that EZ3 motors are now being assembled at our Maysville, Ky. facility with a standard one-week lead time.

Whether it’s a gearbox, motor, or rack and pinion, put down the catalogs and find what you need with a few simple clicks!