STOBER’s cLEAN Drive is designed for optimal control of the cLEAN Motor using a permanent magnet sensorless vector control. Easy to install and program, the cLEAN Drive comes with basic motor parameters already written on the drive.

STOBER’s cLEAN Drive is designed for optimal control of the cLEAN Motor using a permanent magnet sensorless vector control. Easy to install and program, the cLEAN Drive comes with basic motor parameters already written on the drive.

We hope our blog has been informative, useful, and inspiring this year. As a review of 2024, we look back at some of the year’s top blog posts and recap them here. Feel free to browse them again, or check them out if you missed them!

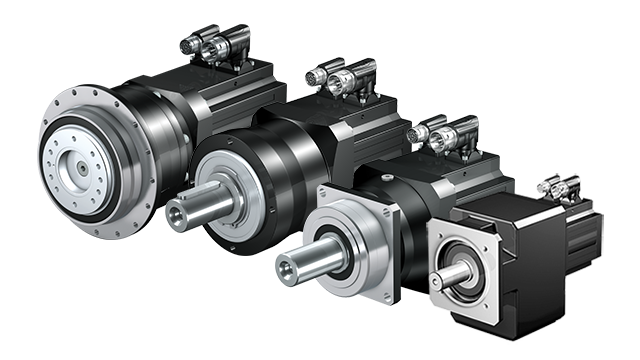

Commissioning a STOBER geared motor with a Bosch drive is easier than you may think. Watch the video for step-by-step instructions.

STOBER has made it even easier for factories to maximize productivity and eliminate unplanned downtime with the cLEAN System. STOBER’s cLEAN System eliminates premature failure due to water ingress, has IE5 energy efficiency, and is designed to EHEDG standards.

Connect with the STOBER team at Automation Fair in Anaheim to “scratch” the surface of learning about STOBER’s solutions for your application! Scratch a ticket to win a cool prize in booth 1221 during Automation Fair Nov. 18-21!

STOBER is the world’s leading expert in solutions for the food processing industry, so it’s no surprise that the cLEAN System is the ultimate solution for harsh washdown environments.

Commissioning a STOBER geared motor with a Siemens drive is easier than you may think. Watch the video for step-by-step instructions.

Through the STOBER Serves volunteer program, STOBER employees have recently contributed 100 hours to beautifying Cummins Nature Preserve. The company is seeking additional volunteer opportunities for its employees.

STOBER Drives has been named Large Business of the Year by the Maysville Area Chamber of Commerce.

A recent project on a pepperoni slicer for an OEM customer proved successful and keeps pizza production as efficient as possible, speeding up the process while eliminating downtime.