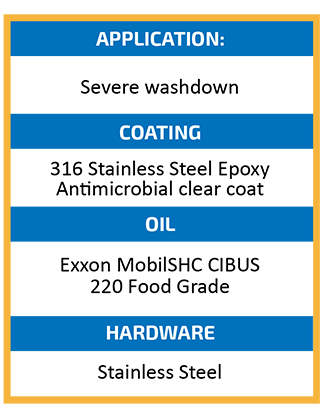

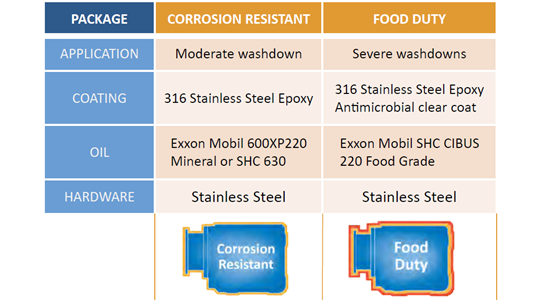

STOBER’s food-duty products thrive in harsh washdown and severely wet applications thanks to their featured antimicrobial coating. STOBER’s food-duty package includes stainless steel hardware and plastic covers, multilayered 316 stainless steel epoxy coating, antimicrobial clear top coat, and Exxon Mobil SHC CIBUS 220 food grade oil.

The Burke antimicrobial clear top coat featured on STOBER’s food-duty packaged products is proven to eliminate the spread of dangerous pathogens and infectious bacterial growth against more than 600 bacteria including legionella, salmonella, e-coli, staph, and more.

Burke’s product is formulated for long-term performance and damages microbes at a genetic level while also remains strong despite the use of strong, corrosive cleaners. STOBER uses the Burke product to protect surfaces during cleaning regimens and keep them safe for human contact because we know how detrimental a health-related recall can be for companies in the food industry.

Burke’s smart release antimicrobial technology includes:

- Sterilization – Prevents cell reproduction once silver has entered the cytoplasm and reacts with genomic DNA. Stops DNA copying.

- Suffocation – Inhibits membrane transport processes by causing the failure of key enzymes associated with transmittance of nutrients across the cell wall.

- Starvation – Interrupts cell metabolism by causing failure of key enzymes associated with respiratory function. Stops energy production.

While many gearboxes aren’t able to handle rigid washdowns and continuous operation, STOBER’s solutions pass the test, preventing premature failure and saving thousands of dollars in downtime.

Some other common food production challenges include:

- Limited preventive maintenance capacity – STOBER’s products are no maintenance and no oil changes, so your maintenance crew can focus on other needs.

- Water ingress – Water ingress doesn’t stand a change against STOBER. Dual output seals and an o-ring on the input create a tight seal to prevent water ingress.

- Premature failure from rigid mounting – STOBER offers torque arm mounting options to prevent premature failure from rigid mounting.

- Leaking gearboxes/food safety – At STOBER, our products are no maintenance and no leaks. No more worry about leaking gearboxes, but we offer food-grade oil to comply with all food safety requirements.

STOBER has experience and product knowledge to solve your food production problems. We’re so confident, we offer the industry’s leading warranty and feature an average mean time to failure in a 24/7 harsh washdown environment of 9.1 years. If that’s not enough, you can count on our 24/7/265 support with emergency shipments available if our already fast delivery just doesn’t cut it. Download the PDF below to learn more about STOBER’s hygienic options for the food industry and give us a call to configure your next solution.

STOBER food-duty gearboxes and geared motors use antimicrobial coating

STOBER food-duty gearboxes and geared motors use antimicrobial coating  STOBER employees deliver donations to flood victims in Floyd County

STOBER employees deliver donations to flood victims in Floyd County  STOBER a proud member of Rockwell Automation PartnerNetwork

STOBER a proud member of Rockwell Automation PartnerNetwork  cLEAN up your act with STOBER’s cLEAN System

cLEAN up your act with STOBER’s cLEAN System