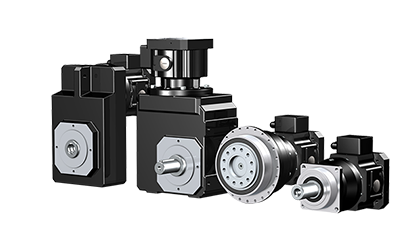

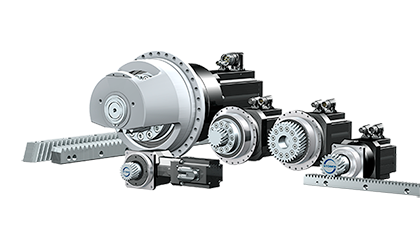

Right Angle Servo Gearboxes

STOBER’s right angle servo gearbox is unrivaled in its options. Choose from planetary gearing or take advantage of helical gearing. Servo doesn’t have to mean planetary! Our ability to develop customized solutions and our commitment to innovation mean these products can fit into virtually any application across multiple industries. Examples of these right angle geared motors can be found in the food processing, packaging, material handling, automotive manufacturing, printing and beverage industries. Their performance and durability make them ideal across a wide range of situations and tolerances.

If our standard equipment doesn’t fit exactly into a customer’s machines, we also have the expertise and capabilities necessary to create custom components. As the leading right angle gearbox manufacturers, we design and build units that save space and simplify your machinery.

These gearboxes can be mounted to any motor with our toleranced motor adapters or you can add a STOBER motor on them to make a geared motor. These units are assembled in our Maysville, Kentucky facility, shipped in one day, and come with a 5 year warranty.

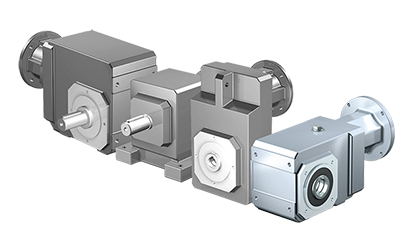

The K/KL series is unparalleled when it comes to right angle options. This servo gearbox’s unique design allows you to use a variety of outputs, including shaft, hollow bore, shrink rings, and bushings.

Housing options include flange, feet, and torque arm.

The K/KL unit features helical bevel gearing, providing smooth motion and optimal efficiency.

K/KL gearboxes are available as compact right angle servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

K/KL Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 4 – 381

- Acceleration torque: 22 – 13,200 Nm

- Nominal torque: 15 – 12,000 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 725 Nm/arcmin

K/KL Series: FEATURES

- Outputs:

- Hollow bore

- Shaft output (K)

- Shaft with or without key (KL)

- Single or double wobble free bushing

- Housing Styles:

- Output flange (Round for K, Square for KL)

- Pitch circle diameter tapped holes

- Foot mounting

- Torque arm bracket

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty - 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty - 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Motor Adapter:

- MQ - standard clamp coupling for KL

- ME – standard clamp coupling for K

- Seal option - MSS1 seal for longer life

- Peak torque booster - pinion securing element for shock loads, increasing peak torque up to 80%

- MB – ServoStop with integrated safety brake

- Environmental Considerations: ATEX Certified Available for explosive environments for K Series

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Available as a geared motor!

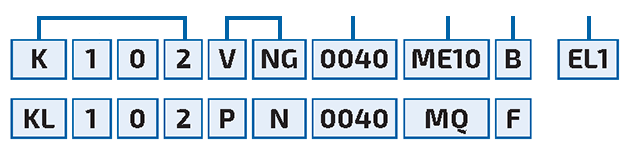

K/KL Series: PART NUMBER EXAMPLE:

The PKX series combines our planetary P series with a KX series input.

This servo gearbox features a compact design and has superior stiffness and precision compared to a K series unit.

PKX gearboxes are available as compact right angle servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

PKX Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 3 – 300

- Acceleration torque: 21 – 3,300 Nm

- Nominal torque: 15 – 2,387 Nm

- Continuous Input Speed: Up to 3,500 RPM

- Cyclic Input Speed: Up to 6,000 RPM

- Torsional Stiffness: Up to 393 Nm/arcmin

PKX Series: FEATURES

- Output Shaft:

- Plain shaft

- Feather key

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Double row angular contact bearing – ideal for high axial loads

- Cylindrical roller bearing – ideal for radial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple.

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Food Duty - 316 stainless steel epoxy paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Motor Adapter:

- MF - flexible coupling, ideal for thermal length compensation

- Seal option - MSS1 seal for longer life

- MF - flexible coupling, ideal for thermal length compensation

- Environmental Considerations: ATEX Certified Available for explosive environments

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Available as a geared motor!

PKX Series: PART NUMBER EXAMPLE:

The KS series gives the benefits of helical bevel gearing while still having low backlash.

You can choose from three different output options, including shaft, flange, and hollow bore.

KS gearboxes are available as compact right angle servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

KS Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 6 – 200

- Acceleration torque: 90 – 400 Nm

- Nominal torque: 60 – 250 Nm

- Continuous Input Speed: Up to 4,500 RPM

- Cyclic Input Speed: Up to 6,000 RPM

- Torsional Stiffness: Up to 42 Nm/arcmin

KS Series: FEATURES

- Outputs:

- Plain shaft

- Shaft with feather key

- Flanged hollow bore

- Shrink ring

- Motor Adapter:

- ME – standard clamp coupling

- MEL - clamp coupling that can accommodate larger diameter motor shaft without upsizing to larger gearbox

- Environmental Considerations: ATEX Certified Available for explosive environments

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Available as a geared motor!

KS Series: PART NUMBER EXAMPLE:

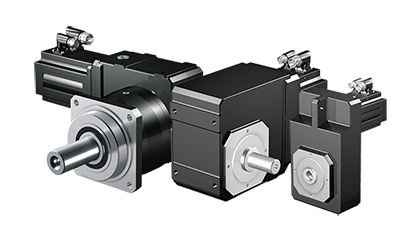

The F series offers compact size and flexibility.

This servo gearbox uses helical bevel gearing for optimal efficiency.

Choose from a variety of housing styles and output options.

F gearboxes are available as compact right angle servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

F Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 4.3 – 552

- Acceleration torque: 78 – 1,100 Nm

- Nominal torque: 69 – 1,100 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 77.4 Nm/arcmin

F Series: FEATURES

- Outputs:

- Hollow bore

- Shaft

- Shrink ring

- Single or double wobble free bushing

- Housing Styles:

- Output flange

- Pitch circle diameter tapped holes

- Foot mounting

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Corrosion Resistant Duty - 316 stainless steel epoxy paint, Exxon Mobil SHC 630 or 600XP220 Mineral, and stainless steel output

- Food Duty - 316 stainless steel epoxy food duty paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Motor Adapter:

- ME – standard clamp coupling

- Seal option - MSS1 seal for longer life

- Peak torque booster - pinion securing element for shock loads, increasing peak torque up to 80%

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Available as a geared motor!

F Series: PART NUMBER EXAMPLE:

The PHK series combines our planetary PH series with a K series input.

This servo gearbox features quiet operation, higher ratios, and higher input speeds compared to a KX series unit.

PHK gearboxes are available as compact right angle servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

PHK Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 16 – 561

- Acceleration torque: 277 – 7,207 Nm

- Nominal torque: 210 – 5,000 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 1,210 Nm/arcmin

PHK Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Coating Options: options for different environments.

- Standard - RAL-9005 black paint

- Washdown - 316 stainless steel epoxy paint

- Motor Adapter:

- ME – standard clamp coupling

- Seal option - MSS1 seal for longer life

- Peak torque booster - pinion securing element for shock loads, increasing peak torque up to 80%

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Available as a geared motor!

PHK Series: PART NUMBER EXAMPLE:

The PHKX series combines our planetary PH series with a KX series input.

This servo gearbox features a compact design and has superior stiffness and precision compared to a K series unit.

PHKX gearboxes are available as compact right angle servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

PHKX Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 4 – 300

- Acceleration torque: 60 – 2,100 Nm

- Nominal torque: 36 – 1,557 Nm

- Continuous Input Speed: Up to 3,500 RPM

- Cyclic Input Speed: Up to 6,000 RPM

- Torsional Stiffness: Up to 489 Nm/arcmin

PHKX Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Backlash:

- Standard

- Reduced - optimized gear hardening ensures smoothness of motion and minimizes velocity ripple

- Coating Options: options for different environments.

- Standard - RAL-9005 black paint

- Washdown - 316 stainless steel epoxy paint

- Motor Adapter:

- MF - flexible coupling, ideal for thermal length compensation

- Environmental Considerations: ATEX Certified Available for explosive environments

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Available as a geared motor!

- Available as a rack and pinion system

PHKX Series: PART NUMBER EXAMPLE:

The PHQK series combines our planetary PHQ series with a K series input.

This servo gearbox features the highest acceleration torque and torque density.

PHQK gearboxes are available as compact right angle servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

PHQK Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 22 – 2,242

- Acceleration torque: 316 – 43,000 Nm

- Nominal torque: 264 – 21,772 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 4,664 Nm/arcmin

PHQK Series: FEATURES

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Reinforced bearing – ideal for high axial loads

- Coating Options: options for different environments.

- Standard - RAL-9005 black paint

- Washdown - 316 stainless steel epoxy paint

- Motor Adapter:

- ME – standard clamp coupling

- Seal option - MSS1 seal for longer life

- Peak torque booster - pinion securing element for shock loads, increasing peak torque up to 80%

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Available as a geared motor!

PHQK Series: PART NUMBER EXAMPLE:

The PK series combines our planetary P series with a K series input.

This servo gearbox offers quieter operation, higher input speeds, and higher ratios compared to a KX unit.

PK gearboxes are available as compact right angle servo geared motors or they can be mounted to any motor with our toleranced motor adapter.

PK Series: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Total gear ratio range: 12 – 561

- Acceleration torque: 200 – 3,105 Nm

- Nominal torque: 120 – 2,100 Nm

- Continuous Input Speed: Up to 4,000 RPM

- Cyclic Input Speed: Up to 7,000 RPM

- Torsional Stiffness: Up to 305 Nm/arcmin

PK Series: FEATURES

- Output Shaft:

- Plain shaft

- Feather key

- Bearings: Options for axial or radial loads

- Standard – ball bearing ideal for some axial and radial load capacity

- Double row angular contact bearing – ideal for high axial loads

- Cylindrical roller bearing – ideal for radial loads

- Package Options: options for different environments. A package includes coating, lubrication, and output material

- Standard Duty - RAL-9005 black paint, Synthetic Exxon Mobil SHC 629, carbon steel output

- Food Duty - 316 stainless steel epoxy paint with anti-microbial clear coat, Exxon Mobil SHC CIBUS 220, and stainless steel output

- Motor Adapter:

- ME – standard clamp coupling

- Seal option - MSS1 seal for longer life

- Peak torque booster - pinion securing element for shock loads, increasing peak torque up to 80%

- MB – ServoStop with integrated safety brake

- ME – standard clamp coupling

- Environmental Considerations: ATEX Certified Available for explosive environments

- Mounting Positions:

- EL1, 2, 3, 4, 5, or 6

- Available as a geared motor!

PK Series: PART NUMBER EXAMPLE:

| Title | Version | ID | Date | Size | ||

|---|---|---|---|---|---|---|

| Servo Gear Units | 33 | 442934 | 2024 06 | EN | 33.97 MB |