cLEAN System

STOBER has been innovating and optimizing gearbox solutions for the food and beverage industry since 1997. Designed with decades of knowledge and experience, STOBER’s stainless steel cLEAN system was created to provide a long-lasting system that improves your plant’s reliability. Durable, efficient, and guaranteed to work in the harshest environments – Upgrade to the world’s toughest system today!

STOBER's cLEAN System eliminates premature failure due to water ingress, has IE5 energy efficiency, and is designed to EHEDG standards. The KSS gearbox and cLEAN Motor is IP68 and IP69K Certified. The cLEAN Drive from STOBER supports numerous communication protocols, such as MODBUS, PROFIBUS, EtherCAT, and EtherNet/IP, and is incredibly easy to program and install.

The entire system (stainless steel reducer and hygienic motor, Ecolab certified cable, and preprogrammed drive) is backed by a three-year warranty.

cLEAN System: TECHNICAL DATA

| $ | $ | $ | $ | $ |

- Speed: 0 – 3000 RPM

- Voltage: 230 or 460

- Motor Horsepower: 1 HP or 2 HP

- Overhung Load Capacity: Up to 8,325 lbs.

cLEAN System: FEATURES

- IP Ratings:

- IP68 and IP69K – Gearbox and Washdown Motor

- IP20 or IP40 – Drive Controller

- EMC Function:

- Built-in EMC Filter Option

- Communication Options

- EtherNet/IP

- MODBUS

- MODBUS TCP

- PROFIBUS

- EtherCAT

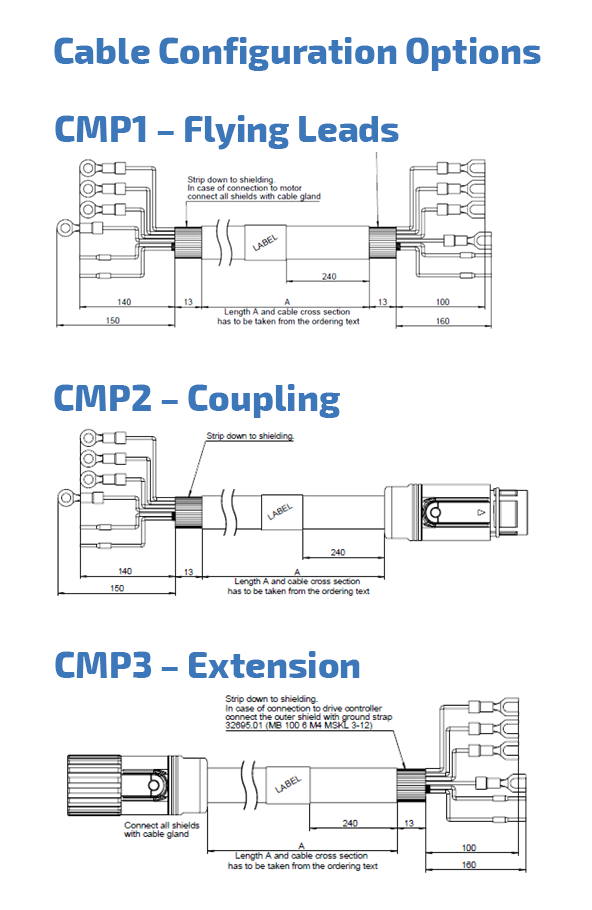

- Cable Configuration Options

- CMP1 – Flying Leads (cable runs from the motor to the disconnect/drive)

- CMP2 – Coupling (cable runs from the motor)

- CMP3 – Extension (cable runs from the drive)

Industries

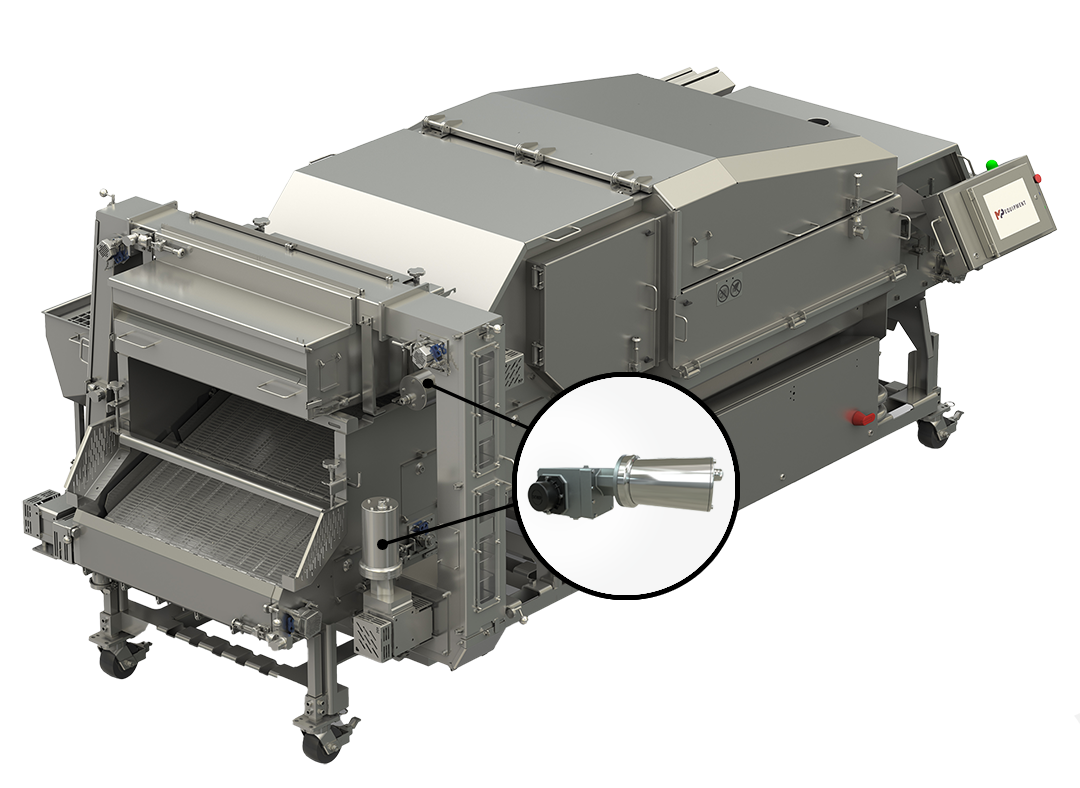

Application Example

What is the STOBER cLEAN System?

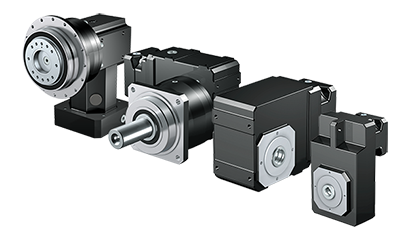

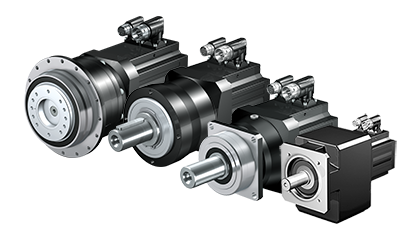

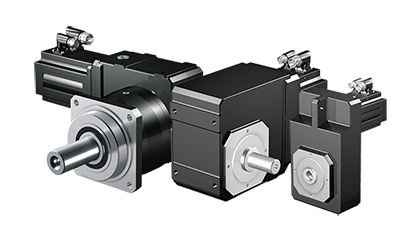

The STOBER cLEAN System is comprised of a KSS stainless steel gearbox, a cLEAN Motor, cLEAN Cable, and cLEAN Drive. It is a full system targeted at heavy washdown applications.

What is the cLEAN Motor?

The STOBER cLEAN hygienic motor is a TENV stainless steel motor. Its design incorporates a 6-pole interior permanent magnet (IPM) design to have higher efficiency and produce torque in a smaller package. The housing design eliminates weep holes and includes redundant seals eliminating premature failure due to water ingress.

Does the cLEAN Motor have totally encapsulated windings?

Our cLEAN Motor winding employs vacuum pressure impregnation to secure individual windings and maintain insulation integrity. This method, coupled with our stator housing's anti-condensation design and redundant sealing system at external interfaces, effectively protects the motor from moisture and cleaning fluid intrusion eliminating the need for total encapsulation.

Is the cLEAN Drive developed by STOBER?

The cLEAN Drive is not developed by STOBER. It is an MH300 VFD from Delta Electronics that is integrated into the cLEAN Ecosystem. STOBER provides full support for the integration and troubleshooting of the cLEAN Drive.

Does the cLEAN Motor need the cLEAN Drive?

The cLEAN Drive is preprogrammed from STOBER to provide the best efficiency and torque to operate the cLEAN motor. The cLEAN Drive has been identified to provide an open loop IPM sensorless control method that aligns with STOBER’s quality.

How can the cLEAN Drive be operated?

The cLEAN Drive has various operation sources and mounting options to fit into any industrial automation design scheme: keypad, external input, MODBUS, MODBUS-TCP EtherNet/IP, PROFIBUS, PROFINET, EtherCat, DIN, etc.

Does the cLEAN System require the cLEAN Cable?

The cLEAN System requires a high quality shielded VFD cable for optimal performance operation. STOBER has identified the best and lowest cost option available to deliver a full solution to our customers at the best cost.

What options are available for the cLEAN Cable?

The cLEAN Cable can be ordered to a specified length with several termination styles e.g. unterminated, flying lead, stainless steel connector. The cLEAN Cable is ordered to a specified length connected to the stainless steel gearmotor and a stand-alone cable for situations where a motor disconnect is installed alongside the washdown motor.

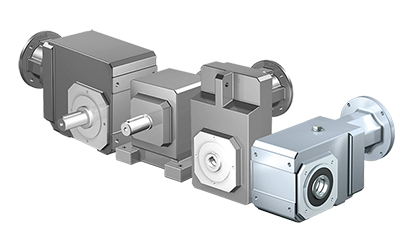

What gearboxes can be used with the cLEAN System?

The cLEAN System is designed to operate with the STOBER gearboxes. The specific models and ratios are shown in the STOBER Catalog.

What certifications does the cLEAN System have?

cLEAN Motor

- IP69K

- IP68

- Designed to EHEDG

- UL

cLEAN System

- IE5 Efficiency Class

- Ultra-Premium Efficiency Class

What support is STOBER providing for the cLEAN System?

STOBER provides pre-sales support for sizing, selection, and configuration of the cLEAN System. In addition, STOBER provides post-sales support for electronics configuration and operation as well as any warranty issues. All of this is at no cost to the customer.

Where can I find product literature for the cLEAN System?

There are several pieces of literature available to the customer for the cLEAN System such as catalog technical specifications, quick start configuration manuals and in-depth user manuals. All the documents can be found on STOBER’s website or included with the equipment.

What is the warranty for the STOBER cLEAN System?

The cLEAN System will have STOBER’s standard 3 year warranty on the entire system.

Is the cLEAN System eligible for next day air?

Yes, the cLEAN System is eligible for STOBER’s next day air.

Are the Drives Stackable?

Yes, the cLEAN Drives are eligible for a Zero Stack Installation method (no clearance between drives) up to 40°C ambient without derating.

Is auto-tuning of the cLEAN Drive required to operate with the cLEAN Motor

The cLEAN Drive is preprogrammed from STOBER to operate effectively with any cLEAN Motor. However, due to manufacturing tolerances, each motor is slightly different. To get the best possible performance out of the motor it is recommended to auto-tune the cLEAN Drive to the cLEAN Motor that it will operate.

What additional hardware is required for the cLEAN System.

If it is necessary to routinely use a motor disconnect to control power to the motor with the drive outputting, an auxiliary contact should be used to simultaneously disable the drive to prevent a fault. The twisted pair in the cLEAN Cable can be used to connect the drive input to the contact. Additionally, if a 120V signal is used for starting/stopping the drive, a separate relay will be needed for interfacing with the drive's control input.

Is it possible to utilize the single twisted pair for both temperature monitoring and activating the auxiliary contact?

No, it is not possible to monitor temperature and activate the auxiliary contact with the single twisted pair. This would require a cable with an additional twisted pair. Both of STOBER’s cable suppliers offer a cable with this configuration; however, it is not currently stocked. This scenario will be handled on a case-by-case basis so please contact STOBER for pricing and lead time.

Is there a NEMA 4 enclosure for the drive available to allow the drive to be installed on the line?

It does exist, but it is not currently a standard offering; however, this is something that can be investigated on a case-by-case basis. Depending on the number of requests for this offering, it could potentially become a standard offering. Contact STOBER for more information.

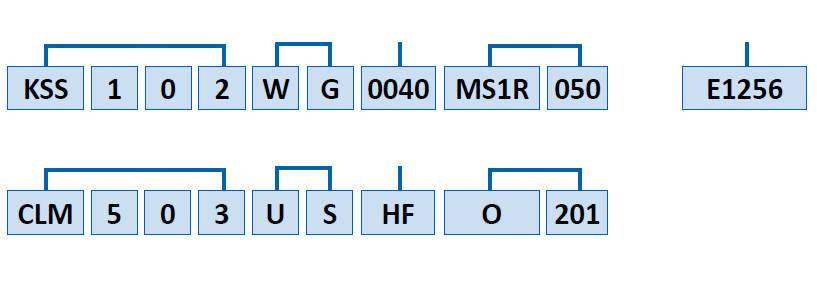

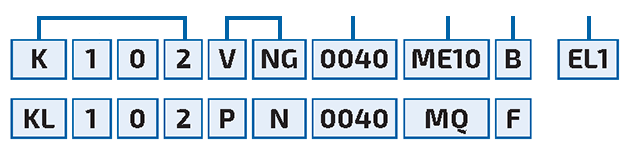

cLEAN System: PART NUMBER EXAMPLE:

| Title | Version | ID | Date | Size | ||

|---|---|---|---|---|---|---|

| Operating manual CLM cLEAN motors | 00 | 443443 | 2024 04 | EN | 1.53 MB |

| Replacement part list cLEAN-Motor CLM | 00 | 443442 | 2024 05 | EN | 470.66 KB |

| EU declaration of conformity cLEAN motors | 00 | 443444 | 2024 04 | EN | 73.02 KB |

| Connection plan motors CLM_HG on Stöber MH300 | 00 | 443446 | 2024 04 | EN | 112.07 KB |

| Connection plan motors CLM_HF on Stöber MH300 | 00 | 443352 | 2024 04 | EN | 248.63 KB |

| Manual cLEAN Drive Configuration with cLEAN Motor | 00 | 442806 | 2024 01 | EN | 1.90 MB |

| cLEAN System Motor Mounting | 00 | 442753 | 2024 01 | EN | 1.35 MB |

| Title | Version | ID | Date | Size | ||

|---|---|---|---|---|---|---|

| Flyer cLEAN System | 01 | – | 2024 01 | EN | 3.82 MB |

| Flyer cLEAN System Drive Overview | 01 | – | 2024 10 | EN | 1.83 MB |

| Flyer cLEAN System Certification | 01 | – | 2024 10 | EN | 1.75 MB |

| Flyer cLEAN Motor Technology Comparison | 01 | – | 2024 10 | EN | 3.64 MB |

| Flyer cLEAN Motor Competitor Comparison | 01 | – | 2024 10 | EN | 4.68 MB |