BEVERAGE INDUSTRY

“The annual downtime for food and beverage production is over 10 weeks a year.” – Harting

Use STOBER’s NEMA right-angle gearboxes for the beverage industry to keep your downtime minimized.

Applications and Solutions in the Beverage Industry

How much is downtime costing you in beverage manufacturing? Find ways to eliminate downtime, optimize your storeroom, and stop premature failure with STOBER’s solutions.

With a three-year warranty and the ability to withstand wet, washdown environments, you won’t find a more durable solution.

COMMON CHALLENGES AND PROBLEMS

1. Continuous operation

2. Expensive downtime

3. Energy consumption

4. Large amounts of inventory

5. Limited preventative maintenance capacity

6. Water ingress

Applications and Solutions for the Beverage Industry

How much is downtime costing you? Find ways to eliminate downtime, optimize your storeroom, and stop premature failure with STOBER’s solutions.

With a three-year warranty and the ability to withstand wet, washdown environments, you won’t find a more durable solution.

COMMON CHALLENGES AND PROBLEMS

1. Continuous operation

2. Expensive downtime

3. Energy consumption

4. Large amounts of inventory

5. Limited preventative maintenance capacity

6. Water ingress

Gear units for every mounting position

STOBER’s NEMA gearboxes require no maintenance. IP69K Certified, USDA Accepted Equipment, and 3 year warranty all mean our products can withstand the harshest washdowns.

CONFIGURE NOW

CONFIGURE NOW

Our servo right angle gearboxes are unrivaled in their options. High-performance, extremely precise, reliable and outstanding in their particularly wide range of adaptations.

Learn more

Learn more

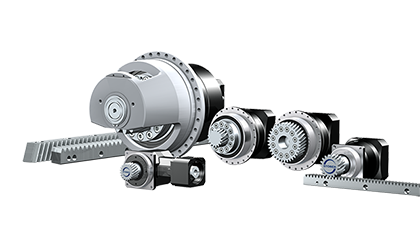

An innovative system concept for rack and pinion drives

With its rack and pinion drives, STOBER offers ready-to-assemble solutions including pinions, gear racks and planetary gearboxes in various designs – all adapted to the different

CONFIGURE NOW

demands for load capacity and precision.

-

ZV – High flexibility for your pick & place application

- Flexible and cost-effective solution

- Pinion position either at the shaft end or shaft shoulder as needed

- Backlash-free, positive-locking shaft-hub connection

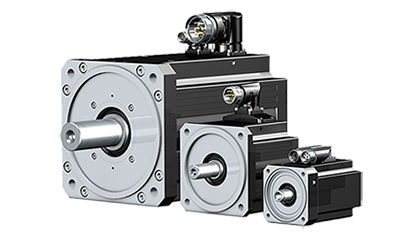

Synchronous servo motors with a high power density

For the highest positioning accuracy and dynamics, choose the extremely compact and resilient STOBER EZ series synchronous servo motors.

- Super-compact

- Maximum torque

- High dynamics

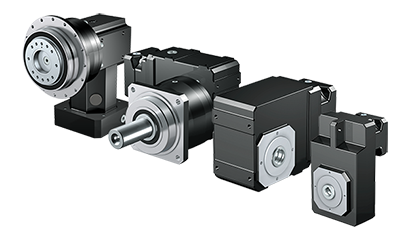

The most compact planetary geared motors on the market

The new STOBER planetary gearboxes are the most compact on the market in terms of versatility. The excellent housing and gearing quality ensures high acceleration torques as well as the highest running accuracy and precision at the same time.

CONFIGURE NOWPractical without any compromises – servo geared motors

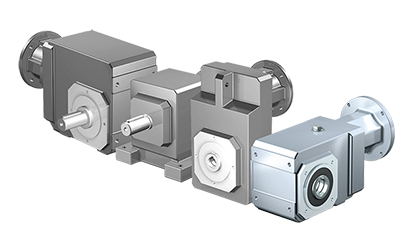

Are you looking for higher dynamics, lower weight, and very small installation space for the angular transmission of motion and forces? The solution from STOBER is the KL series of helical bevel gearboxes!

CONFIGURE NOW

CONFIGURE NOW

- Made from one mold

- Combined with STOBER synchronous servo motors, this means a coupling-free connection that reduces the space requirement, the rotating masses and the associated weight

- Extremely attractive price-performance ratio