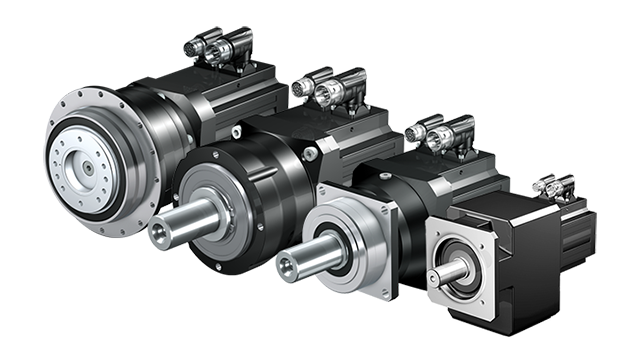

Did you know that the world’s toughest gearbox doesn’t require oil changes? STOBER’s KSS stainless steel, K, C, and F series reducers (in food-duty or corrosion-resistant options) require no maintenance due to efficient gearing, housing design, quality components, and expert assembly.

Oil changes can cost more than $250 each for every line location and some units may require multiple oil changes per year. Utilizing a factory-filled, no-maintenance gear reducer that is lubed for life eliminates the need for oil drip pans & drain lines and reduces harborage risk.

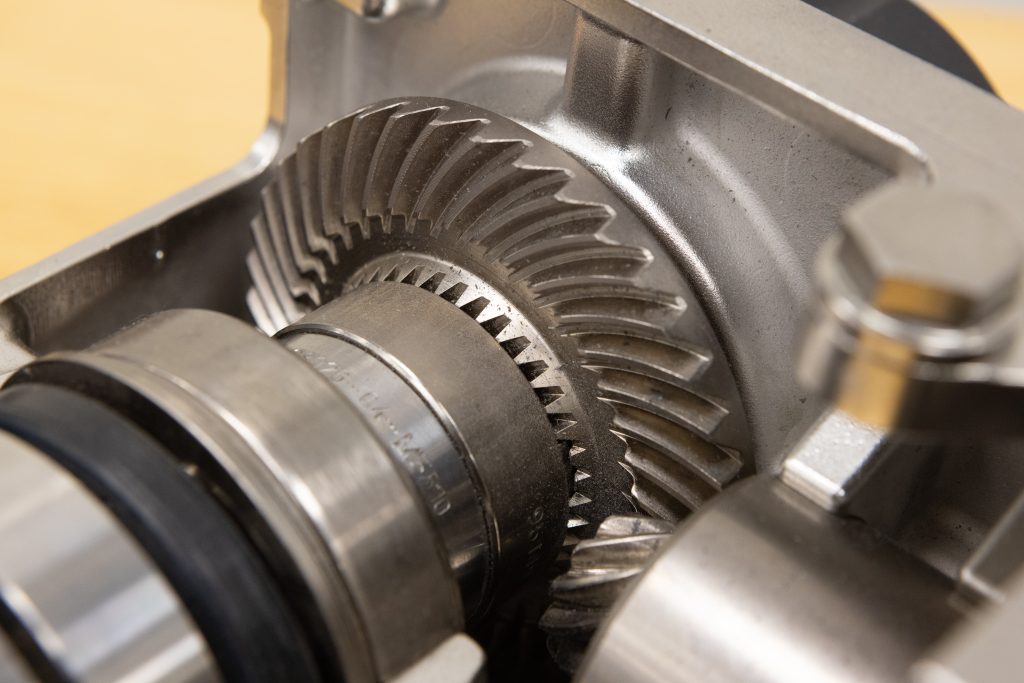

STOBER gear reducers use high-quality double output seals to prevent oil leaks and water ingress. Combining quality inputs with the tightest machining tolerances & assembly practices ensures product longevity. Our products are both IP69K certified and USDA Accepted Equipment, which means they are equipped to handle caustic environments.

In addition, STOBER reducers have all gear teeth ground prior to assembly and use neodymium magnetic drain plugs to attract ay wear particles out of the oil bath, preventing them from reaching bearing races and critical seal lips.

Reducer housings can dissipate the heat generated during operation much more quickly than the unit can build up thermal pressure, so a breather is not required to vent thermal pressure. Since the units don’t have a breather, they are completely sealed and don’t require preventive maintenance oil changes. All STOBER corrosion resistant units are filled with Exxon Mobil SHC 630 and food duty units are filled with SHC Cibus 220-H1.

With a three-year warranty and an average mean time to failure of 9.1 years in harsh washdown environments, STOBER gear reducers are the best for preventing unplanned downtime. Combining quality inputs with the tightest machining tolerances and assembly practices ensures product longevity.

Asset reliability means you can depend on a STOBER gear reducer for years, increasing profits and surpassing plant efficiency and targets. Learn more about STOBER’s no-maintenance NEMA gearboxes at the link below, or contact us at (888) 786-2371 or email sales@www.stober.com.

Meet the engineers behind STOBER innovation

Meet the engineers behind STOBER innovation  Understanding the different types of geared motors

Understanding the different types of geared motors  Synchronous vs. asynchronous motors: The foundation of servo technology

Synchronous vs. asynchronous motors: The foundation of servo technology  How to calculate gear reduction: Formula, examples & applications

How to calculate gear reduction: Formula, examples & applications