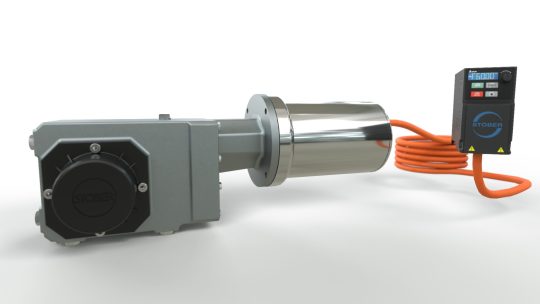

We’ve told you about our products being IP69K certified, but what goes into IP69K testing?

IP69K certification rating has two elements of testing: level of protection against solid matter such as dust, and level of protection against water ingress. The passing criterion for each is no ingress of foreign particles or liquids inside the gearbox or motor.

The liquid testing element includes spraying the geared motor with 176 degrees Fahrenheit/80 degrees Celsius water at a flow rate of four gallons/minute and a pressure between 1160-1450 psi.

For our new cLEAN System, the test was performed with the geared motor running and at standstill. The motor and gearbox were both disassembled with no signs of water in any of the internal cavities or oil.

The dust testing element consists of the geared motor being enclosed in a chamber filled with dust in fineness similar to talcum powder. The test lasts a little over five hours with the dust being recirculated for six seconds every 15 minutes. This results in 20 cycles.

The cLEAN geared motor was running the entire duration of the test. The motor and gearbox were both disassembled with no signs of dust in any of the internal cavities or oil. IP69K Certification is just another reason STOBER’s cLEAN System is the toughest system on the market.

To learn more about STOBER’s new IP69K-certified cLEAN System, click the link below.

Year in review: Top blog posts of 2025

Year in review: Top blog posts of 2025  The Christmas miracle: How STOBER delivered when it mattered most

The Christmas miracle: How STOBER delivered when it mattered most  Industrial gearbox maintenance: Best practices for reliability and performance

Industrial gearbox maintenance: Best practices for reliability and performance  Meet the engineers behind STOBER innovation

Meet the engineers behind STOBER innovation