Gearbox and motor manufacturers have no choice but to evolve to meet demands of increasing factory productivity and eliminating unplanned downtime. STOBER’s cLEAN system was created to provide a long-lasting system that improves plant reliability. Durable, efficient, and guaranteed to work in the harshest environments–it’s the world’s toughest system.

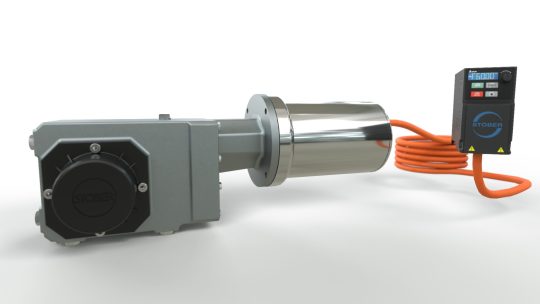

STOBER’s cLEAN System eliminates premature failure due to water ingress, is IP69K certified with an IE5 energy efficiency, and is designed to EHEDG standards. The entire system (stainless steel gearbox and motor, Ecolab certified cable, and preprogrammed drive) is backed by a three-year warranty.

If that’s not enough, check out more details of the cLEAN System’s top three benefits:

- The cLEAN System reduces unplanned downtime, especially when it was previously occurring due to premature failure of a component. The number one cause of premature failure for gearboxes is water ingress through motor weep holes. When water enters the gearbox and motor connection area, the unit fails after the input pinion and bearing rusts, damaging the input seal. This leads to expensive unplanned downtime, high replacement costs, and lost productivity. STOBER’s cLEAN System has eliminated these problems by featuring a completely enclosed solution made up of an all-stainless-steel motor with zero weep holes, double seals on the motor cover and all connection points, and an o-ring in the cable connection. The cLEAN System is designed to EHEDG standards and is IP69K Compliant. When paired with our KSS stainless steel gearbox, the result is the world’s toughest system.

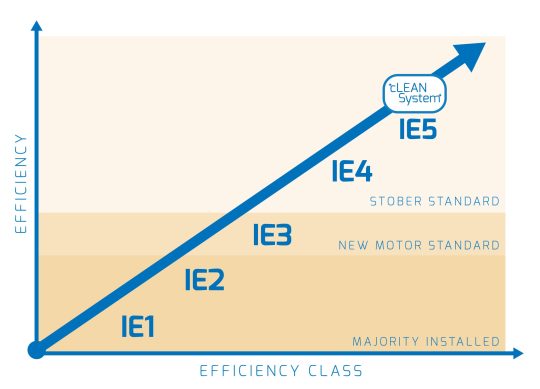

2. The cLEAN System is IE5 level for energy efficiency. Heat kills – inefficient motors run hot, which can shorten their running life. While most existing installed NEMA motors are rated IE2, current regulations for new motor installations call for IE3. But at STOBER, we go above and beyond. The new cLEAN System exceeds energy efficiency regulations, operating at an IE5 level of efficiency. This far exceeds the current base of installed motors in the U.S. and also exceeds future efficiency requirements. In addition to saving thousands of dollars in energy expenditures, the cLEAN System also provides a much more compact solution! Permanent magnet technology allows the cLEAN motor to produce equivalent horsepower of a traditional NEMA motor while measuring 2/3 the size of competitor motors. Not only does the cLEAN motor boast the ultimate energy efficiency, it does so in a smaller envelope.

3. The cLEAN System is easy to install. The motor easily mates to the gearbox and the drive can be programmed in a few minutes. This saves you valuable time and doesn’t require a specialist for installation. The cLEAN System is compatible with MODBUS, PROFIBUS, EtherCAT, and EtherNet/IP. You can use the network of your choice!

On top of all these benefits, you’ll never have to worry about long lead times with the cLEAN System. The STOBER cLEAN System is built and shipped in less than one week from our Maysville, Ky. facility. Not only will you get it fast, but it’s made to last! Learn more about the cLEAN System by clicking the button below. For assistance, contact us at (888) 786-2371 or email sales@www.stober.com.

The Christmas miracle: How STOBER delivered when it mattered most

The Christmas miracle: How STOBER delivered when it mattered most  Industrial gearbox maintenance: Best practices for reliability and performance

Industrial gearbox maintenance: Best practices for reliability and performance  Meet the engineers behind STOBER innovation

Meet the engineers behind STOBER innovation  Understanding the different types of geared motors

Understanding the different types of geared motors