If recent press about E. coli infections has you hesitant to eat at restaurants, you’re not alone. But what about hygiene on the factory floor? Harborage points on gearboxes can allow bacteria to grow on the surface and non-stainless options will rust or cause other issues. STOBER’s stainless-steel, hygienic gearboxes are a must for food-safe factory floors.

In 2011, the U.S. Food and Drug Administration (FDA) implemented the Food Safety Modernization Act (FSMA), which shifted federal safety standards from responding to foodborne illness to proactively preventing it with safer equipment and more stringent cleaning practices. Investing in STOBER gearing solutions keeps manufacturing facilities ahead of the curve, meeting FSMA standards and exceeding sanitation requirements.

Consider the following when choosing hygienic gearing solutions for the food and beverage industry:

- Revenue – The average direct cost of a recall is $10 million for food companies. More than half of customers will switch brands at least temporarily following a food recall. Choosing the correct tooling solution is important to minimize downtime and contamination.

- Efficiency & Durability – Durable, high-efficient gearboxes minimize downtime, produce less heat, and reduce maintenance. Plus, helical bevel gear boxes have long-life warranties and an average mean time to failure of 9.1 years.

- Caustic Washdowns – Stainless steel options may be a more costly initial investment, but they eliminate oxidation concerns and paint contamination issues. To adhere to sanitary designs in the FDA’s Good Manufacturing Practices (GMPs) for all foods, equipment must be cleanable to the microbiological level.

- Compliance – IP69K certified gearing tolerates extreme conditions including extreme dust, contaminants, and high pressure washing and withstands caustic solutions used for severe washdown applications.

- Hygienic Design – There’s no keyway in STOBER’s wobble-free bushing, meaning no harborage points to be breeding grounds for bacteria. The hygienic design prevents bacteria from living on the surface and stainless-steel options withstand harsh chemicals.

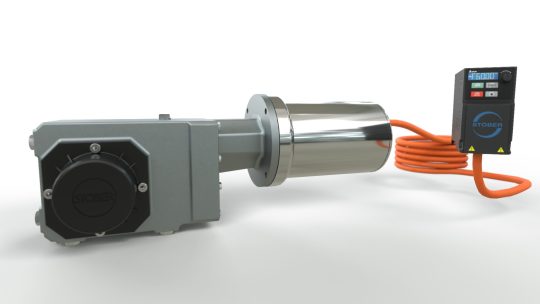

- The Power of One – Now STOBER has made it even easier for factories to maximize productivity and eliminate unplanned downtime with the cLEAN System. STOBER’s cLEAN System eliminates premature failure due to water ingress, has IE5 energy efficiency, and is designed to EHEDG standards. The KSS gearbox and cLEAN Motor is IP68 and IP69K Certified. The cLEAN Drive from STOBER supports numerous communication protocols, such as MODBUS, PROFIBUS, EtherCAT, and EtherNet/IP, and is incredibly easy to program and install. The entire system (stainless steel reducer and hygienic motor, Ecolab certified cable, and preprogrammed drive) is backed by a three-year warranty.

STOBER gearboxes are IP69K certified, USDA Accepted equipment, and boast an average mean time to failure of 9.1 years with a 3-year standard warranty. Built and shipped in less than one week from Maysville, Ky/, STOBER products are ready to take on your harsh washdown challenges!

Contact sales@www.stober.com, call (888) 786-2371, or download our free guide below for more information.

Eight warning signs that you need industrial gearbox repair

Eight warning signs that you need industrial gearbox repair  What is a planetary gearbox and how does it work?

What is a planetary gearbox and how does it work?  Keyed vs. keyless connections: What’s the difference and why does it matter?

Keyed vs. keyless connections: What’s the difference and why does it matter?  2025 STOBER scholarship winners announced

2025 STOBER scholarship winners announced