Released in early 2024, STOBER’s new cLEAN System continues to collect accolades. The KSS gearbox and cLEAN Motor recently received IP68 certification in addition to the already-existing IP69K certification, IE5 energy efficiency, and design to EHEDG standards.

IP68 certification ensures that products are protected against the effects of temporary immersion in water. The STOBER cLEAN System has zero weep holes, features double seals on the motor cover and all connection points, and has an o-ring in the cable connection, resulting in a totally enclosed solution that prevents premature failure.

Ingress Protection (IP) ratings give a quick snapshot of an electrical enclosure’s protective qualities and are one of the most widely used ways to rate water and dust resistance. IP68 ratings occupy the very top of the IP rating scale with both the first digit and second digit at their maximum level: a 6 for total protection against solid ingress, and an 8 for total protection against water ingress, up to and including complete submersion below one meter for more than 30 minutes.

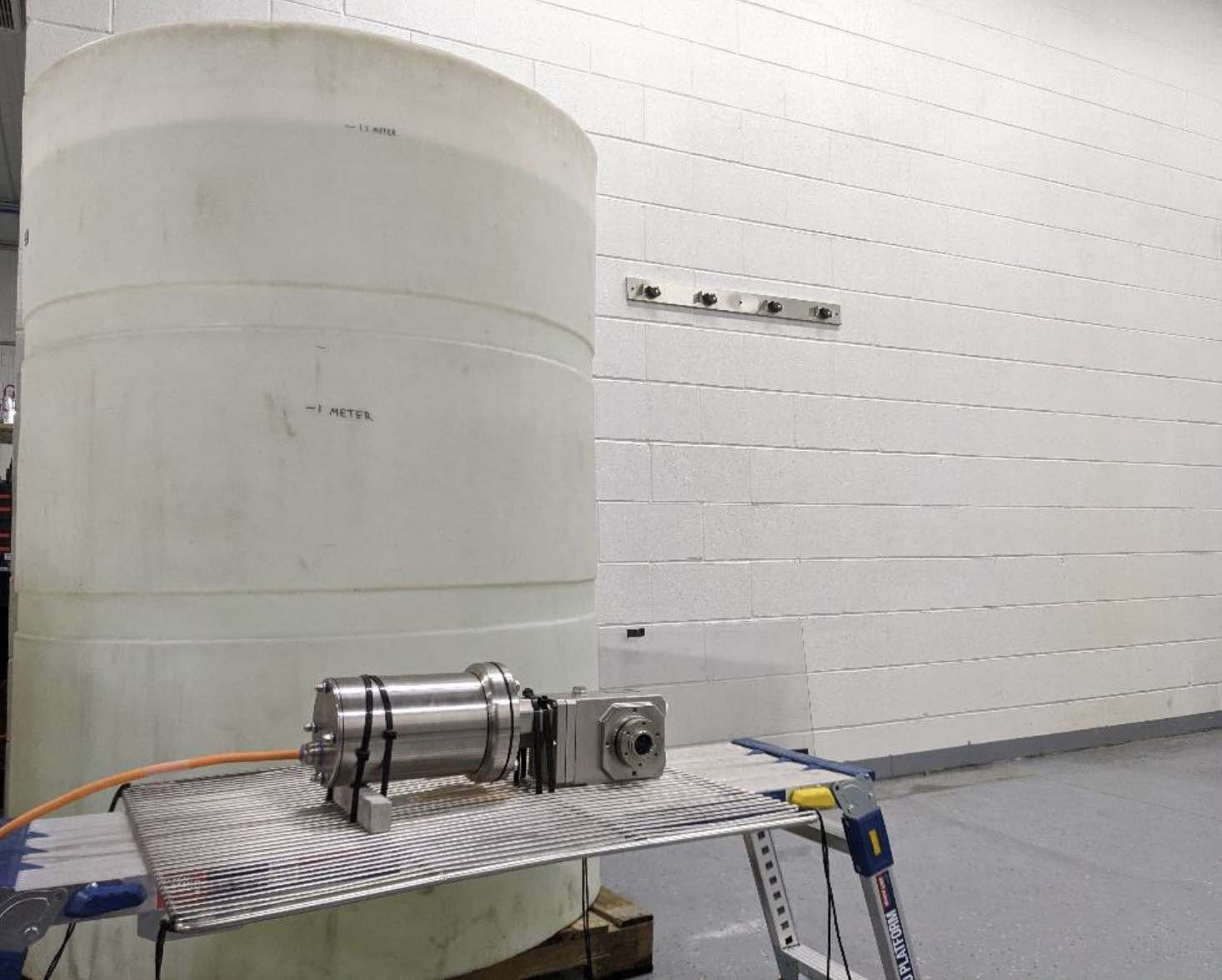

During the IP68 testing, the STOBER cLEAN Motor and KSS gearbox are immersed in water at a depth of 1.5 meters for 30 minutes with the unit powered on and running at full capacity for the duration of the test. Test results noted that “post-test inspection revealed no visible damage, defects, or any other abnormalities,” meaning the products met the requirements of the specification. The results of the test revealed the degree of protection, indicating “ingress of water in quantities causing harmful effects shall not be possible when the enclosure is temporarily immersed in water under standardized conditions of pressure and time.”

IP69K certification proves that the products can withstand harsh washdowns. Further designed for harsh washdown environments, The STOBER cLEAN Motor has a rounded surface finish with no harborage points, meaning no bacteria can grow on the motor. If additional cleaning is needed beyond the exterior, the o-ring can be removed and the unit can be reassembled easily. The easy-to-clean design meets EHEDG standards to prevent microbiological problems, prevent ingress or growth of micro-organisms, and ensure long-term durability.

STOBER’s cLEAN system was created to provide a long-lasting system that improves plant reliability. The entire system (stainless steel gearbox and motor, Ecolab certified cable, and preprogrammed drive) is backed by a three-year warranty. Durable, efficient, and guaranteed to work in the harshest environments–it’s the world’s toughest system.

Click the link below to learn more about STOBER’s cLEAN System.

Eight warning signs that you need industrial gearbox repair

Eight warning signs that you need industrial gearbox repair  What is a planetary gearbox and how does it work?

What is a planetary gearbox and how does it work?  Keyed vs. keyless connections: What’s the difference and why does it matter?

Keyed vs. keyless connections: What’s the difference and why does it matter?  2025 STOBER scholarship winners announced

2025 STOBER scholarship winners announced