Inline geared motors, right angle geared motors, geared motors with rack and pinion, geared motors with fans, geared motors with brakes – STOBER has the range you need for your application:

Inline geared motors

Designed specifically to tackle some of the most rugged applications across multiple industries, these motors are available as either planetary geared motors or as helical geared motors. Compact. Dynamic. Cooler. Adaptable. Packed with the STOBER guarantee – unparalleled service and support and an unmatched warranty of two years!

Right angle geared motors

STOBER servo right-angle geared motors are available as planetary right-angle geared motors and helical-bevel geared motors. All drive units are provided with high-quality helical gearing for unrivalled smoothness of running and backlash stability. Super compact synchronous right-angle servo motors are ideal for highly dynamic applications.

Geared motors with Rack & Pinion

Every rack and pinion servo motor system uses STOBER’s superior servo geared motors. These pinions work with a variety of rack options, including helical. Our range of rack and pinion motors provide exceptional performance in a wide spectrum of high-speed and high-force applications. By combining them with our planetary or helical bevel gearboxes and STOBER servo motors, you get the benefit of extremely compact, highly dynamic drive solutions.

Geared motors with fans

Increase torque and cool your system without upsizing to a larger motor! Heat is the natural enemy of a gearbox – so why not bring that down? In a study performed in our labs, our STOBER Synchronous Servo Geared motor could run up to 14 degrees (F) cooler than the competition – cool, right? Packaging machines often run at higher speeds, increasing ambient temperature. Using a STOBER geared motor can reduce heat and add to equipment life. Add a fan to bring down the temperature even more!

Geared motors with brakes

STOBER’s servo gearboxes can be paired with our ServoStop, an integrated safety brake. It’s ideal for vertical applications and provides redundant braking. It prevents slipping or falls, even when the motor is removed. The ServoStop external servo motor brake provides dynamic braking during power failures or emergencies, helping your operations achieve maximum safety conditions. It fits all standard servo motors and allows for dismounting of the motor even while it is engaged, meaning installation and maintenance is as simple and convenient as it can be.

cLEAN motor

STOBER’s new cLEAN System features the cLEAN motor, which is stainless steel and has a rounded surface finish with no harborage points. No bacteria can grow on the motor, making it ideal for food manufacturing and harsh washdown environments. The cLEAN System features zero weep holes, double seals on the motor cover and all connection points, and has an o-ring in the cable connection, resulting in a totally enclosed solution that prevents premature failure. It’s designed to EHEDG standards and is IP69K Certified. If you do need to do additional cleaning beyond the exterior, the o-ring can be removed for cleaning and the unit can be reassembled easily.

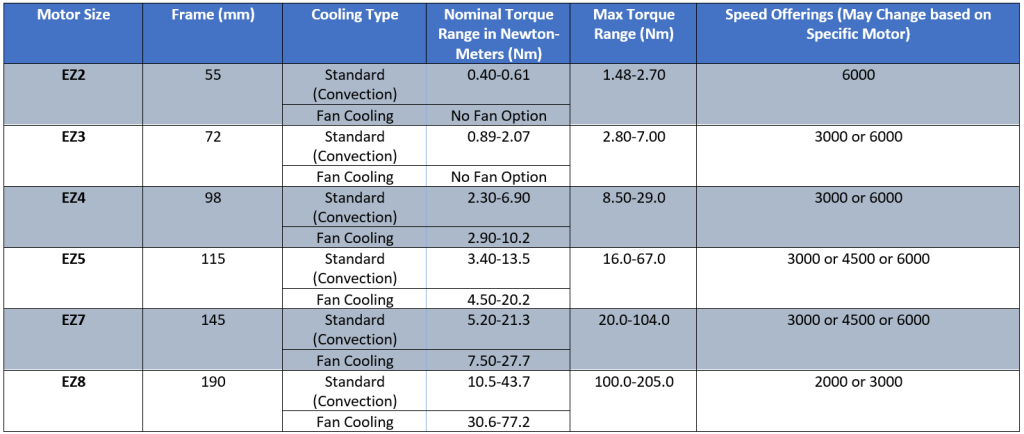

Motor frame sizes

To add to the benefits of STOBER motors, there are a variety of motor frame sizes available, including:

The power of one is always a plus! STOBER geared motors feature one part number, one vendor, one source for gearbox and motor, and one mechanical assembly that works with different third-party controllers. Having everything as one packaged unit helps reduce the need to have to contact multiple vendors for support.

Sized and built in Maysville, Ky., STOBER geared motors feature quick lead time. Contact us today for our expert design analysis that provides you the best options for your application. Learn more about STOBER’s servo motor solutions by clicking the link below.

Keyed vs. keyless connections: What’s the difference and why does it matter?

Keyed vs. keyless connections: What’s the difference and why does it matter?  2025 STOBER scholarship winners announced

2025 STOBER scholarship winners announced  Don’t get caught with your plants down – rely on STOBER’s cLEAN System

Don’t get caught with your plants down – rely on STOBER’s cLEAN System  STOBER food-duty gearboxes and geared motors use antimicrobial coating

STOBER food-duty gearboxes and geared motors use antimicrobial coating