Did you know that premature gearbox failure can be caused by gearing misalignment? Keep reading to find out how premature failure can be eliminated by ensuring proper alignment.

Issues with hollow output gear reducers and conveyor bearings

Hollow output gear reducers are mounted directly on the conveyor shaft on most conveyor systems. In many cases, conveyor bearings may not be completely aligned and shafts may not precision-machined or ground, which can cause shafts to be non-concentric to the reducer bore.

Why rigid mounting gear isn’t recommended

Users often install the gear reducer on the conveyor with a pedestal mount or metal bracket, which fixes the gearbox to the conveyor and prevents the gear reducer from spinning during operation. However, this can cause premature failure due to shaft runout. Since the shaft isn’t truly aligned to the gearbox, it creates radial loads on both the conveyor and the reducer bearing. This pressure can cause the bearings to fail, which could lead to fracture or breakage of the conveyor shaft.

Prolonged overhung loads can be a major maintenance challenge, costing time and money. Some movement or wobbling of the gear reducer on the conveyor shaft is normal and should not be constrained.

Recommended ways to mount a gear reducer

The best method to use when mounting a gear reducer is a torque arm, which allows the gear reducer to float with the run-out on the shaft, eliminates bearing and shaft fatigue, and transmits the torque effectively.

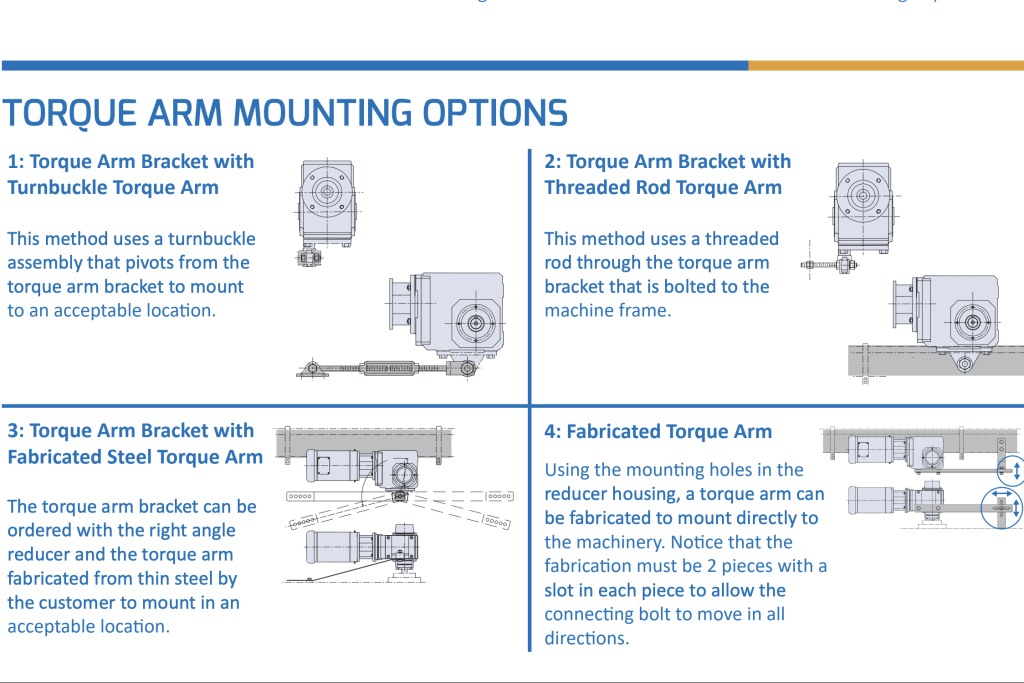

There are several common ways to mount a torque arm to a gear reducer. Reducers can be supplied with a torque arm bracket or customers can choose to fabricate their own free-floating mounting assemblies, which include a turnbuckle, threaded rod, or fabricated stainless steel torque arm. A keyless bushing system allows the same gear reducer to be utilized on different size shafts by simply supplying a different bushing kit size.

What makes STOBER’s products and services stand out

STOBER gear reducers can be torque arm mounted. Using our keyless bushing system means you will never have to cut a reducer off the conveyor shaft again. Having a reducer that can utilize multiple bushing kit sizes also reduces the inventory you need.

We offer onsite installation training for your entire maintenance team and we’re available 24 hours a day, seven days a week for any questions you might have. With an average meantime to failure of over 9.1 years in harsh washdown applications, we know how to make gear reducers that last.

Want to learn more about rigid mounting failure and how to eliminate it? Download our free guide to find out how STOBER has helped a customer overcome rigid mounting below.

What is a planetary gearbox and how does it work?

What is a planetary gearbox and how does it work?  Keyed vs. keyless connections: What’s the difference and why does it matter?

Keyed vs. keyless connections: What’s the difference and why does it matter?  2025 STOBER scholarship winners announced

2025 STOBER scholarship winners announced  Don’t get caught with your plants down – rely on STOBER’s cLEAN System

Don’t get caught with your plants down – rely on STOBER’s cLEAN System