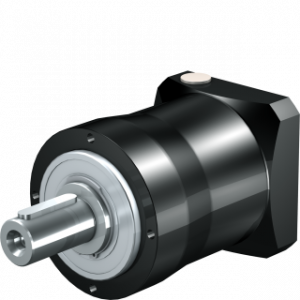

A planetary gearbox is a compact, efficient mechanical system used to transmit torque and control speed. It consists of three main components: the sun gear, planet gears, and ring gear, all held together by a carrier. This unique configuration enables precise motion control and high torque density, making planetary gearboxes essential in industries like automotive, robotics, and industrial machinery.

Compared to other gearbox types, planetary gearboxes stand out for their ability to distribute torque evenly, enhancing durability and efficiency. Their compact design makes them ideal for applications where space is limited, yet performance is critical. Industries requiring precision, such as robotics and automotive, benefit greatly from these systems. Explore our products for the best planetary gear set solutions for your needs.

Components of a planetary gearbox

The performance of a planetary gearbox relies on its expertly designed components:

- Sun Gear: The central gear that drives the system, providing input power.

- Planet Gears: Surrounding the sun gear, these gears orbit around it and engage with the ring gear to transfer torque.

- Ring Gear: Encasing the planet gears, it facilitates torque distribution to the output shaft.

- Carrier: Holds the planet gears in place and ensures smooth motion transfer to the output.

Together, these components work in harmony within the planetary gear system to evenly distribute loads, reducing wear and increasing efficiency.

How does a planetary gearbox work?

The planetary gear system achieves high torque and low speed through its innovative design. Power flows from the input shaft to the sun gear, causing the planet gears to orbit and engage with the stationary ring gear. This simultaneous interaction creates multiple points of contact, distributing loads efficiently and minimizing energy loss.

This gear ratio optimization makes planetary gearboxes ideal for applications requiring durability and heavy-duty performance, such as industrial machinery, wind turbines, and automotive systems.

Types of planetary gearboxes

Planetary gearboxes are versatile, with several types designed for specific needs:

- Single-Stage Gearboxes: Suitable for moderate torque and speed adjustments, often used in compact applications.

- Multi-Stage Gearboxes: Provide higher torque and greater speed reductions, ideal for demanding industrial environments.

- Compact Designs: Lightweight and space-efficient, these are perfect for robotics and electric vehicles where size and weight are critical.

Each type offers unique advantages, allowing users to select the best planetary gearbox for their application.

Advantages of planetary gearboxes

Planetary gearboxes offer several key benefits:

- High Torque Density: Compact size delivers powerful performance.

- Compact Design: Fits into tight spaces without compromising efficiency.

- Load Distribution: Shares forces across multiple gears, reducing wear and enhancing durability.

- Versatility: Adapts to various industries, from automotive to industrial machinery.

These advantages make planetary gearboxes a preferred choice for precision and reliability.

Applications of planetary gearboxes

Planetary gearboxes are indispensable in many industries:

- Automotive: Ensures smooth, reliable operation in automatic transmissions.

- Robotics: Provides compact and precise motion control for advanced robotics.

- Industrial Machinery: Handles heavy loads in conveyors, mixers, and cranes.

- Wind Turbines: Facilitates efficient energy transfer in renewable energy systems.

Explored our industries served and applications for planetary gearboxes to learn more.

Choosing the right planetary gearbox

Selecting the right planetary gearbox involves evaluating:

- Torque and Speed Requirements: Ensure the gearbox matches the application’s specifications.

- Size and Environment: Choose a design that fits within space constraints and withstands environmental conditions.

- Durability and Materials: Opt for high-quality materials to ensure long-term performance.

At STOBER, we offer expert guidance to help you balance initial investment with long-term reliability for optimized performance.

The future of efficiency: planetary gearboxes

Planetary gearboxes blend efficiency, durability, and compactness to excel in various applications. Their advanced design is essential for industries like robotics, automotive, and heavy machinery. As technology advances, planetary gearboxes will continue to drive innovation and operational excellence.

STOBER is a trusted provider of cutting-edge planetary gearboxes, offering customized solutions tailored to meet modern industry demands. Whether you need precision motion control or heavy-duty torque transmission, we deliver the reliability and performance you need.

When it comes to servo inline gearboxes, STOBER’s products are unrivaled in precision and options. STOBER’s planetary products feature unparalleled precision, power, and flexibility. Plus, you can choose from several bearing options to handle radial or axial loads, optimizing your machine design. Both the P and PH gearboxes are available as compact planetary servo geared motors or they can be mounted to any motor with our toleranced motor adapter. These units are assembled in our Maysville, Ky. facility, shipped in one day, and come with a 5-year warranty.

Learn more about planetary options from STOBER by clicking the link below or contact us at (888) 786-2371 or email sales@www.stober.com.

What is a planetary gearbox and how does it work?

What is a planetary gearbox and how does it work?  Keyed vs. keyless connections: What’s the difference and why does it matter?

Keyed vs. keyless connections: What’s the difference and why does it matter?  2025 STOBER scholarship winners announced

2025 STOBER scholarship winners announced  Don’t get caught with your plants down – rely on STOBER’s cLEAN System

Don’t get caught with your plants down – rely on STOBER’s cLEAN System