Effective communication and collaboration between OEMs and suppliers are essential for resolving issues, addressing changes, and fostering long-term partnerships. STOBER’s commitment to clear and consistent communication provides peace of mind that comes with seamless collaboration and transparent updates, allowing OEMs to focus on core business objectives while STOBER handles the details.

Ensuring consistent quality standards for critical components like gearboxes, drives, and motors is paramount, but can be challenging for OEMs to maintain across various suppliers. Streamlined sourcing from STOBER provides production efficiency, optimal support, and swift ordering process.

Learn more about how STOBER helps OEMs ensure success:

- Technical expertise and support: Access to timely technical support and expertise from suppliers is crucial, especially for troubleshooting and integration of complex systems. With comprehensive support from STOBER, OEMs can confidently maximize the performance of machines, reduce costs, and stay ahead of the competition.

- Supply chain reliability: Dependent on timely and reliable deliveries of components, any disruptions in the supply chain can halt production and impact project timelines. Experience seamless production flow and accelerated time-to-market with STOBER.

- Cost management: Balancing the cost of high-quality components with overall project budgets is a constant concern for OEMs, especially in a competitive market. STOBER’s long-term durability is a proven cost savings over the life of the gearbox.

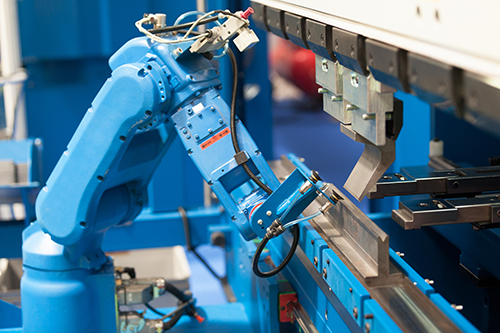

- Compatibility and integration: Ensuring seamless integration of different components within the machine tool system is essential to avoid compatibility issues and optimize performance. With STOBER’s tailored solutions, you can trust in the synchronized collaboration of motors and drive controllers, ensuring consistent performance, reduced downtime, and enhanced productivity.

- Regulatory compliance: Compliance with industry regulations and standards, such as safety and environmental requirements, adds complexity and potential risk if not met by suppliers. STOBER strives to stay steps ahead of regulatory requirements, ensuring the machine is future-proof.

- Innovation and technology adoption: Keeping pace with technological advancements and innovation in gearboxes, drives, and motors is crucial for staying competitive in the rapidly evolving machine tool industry.

- Lead time reduction: Lengthy lead times for components can delay production schedules and affect time-to-market for machine tools, posing challenges for OEMs. Benefit from STOBER’s proven supply chain dependability, empowering OEMs with seamless project management and execution to keep machine timelines intact.

Learn more about STOBER’s solutions for the machine tool industry by clicking the button below. For assistance, contact us at (888) 786-2371 or email sales@www.stober.com.

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor  Selecting gearboxes for robotic & industrial automation systems

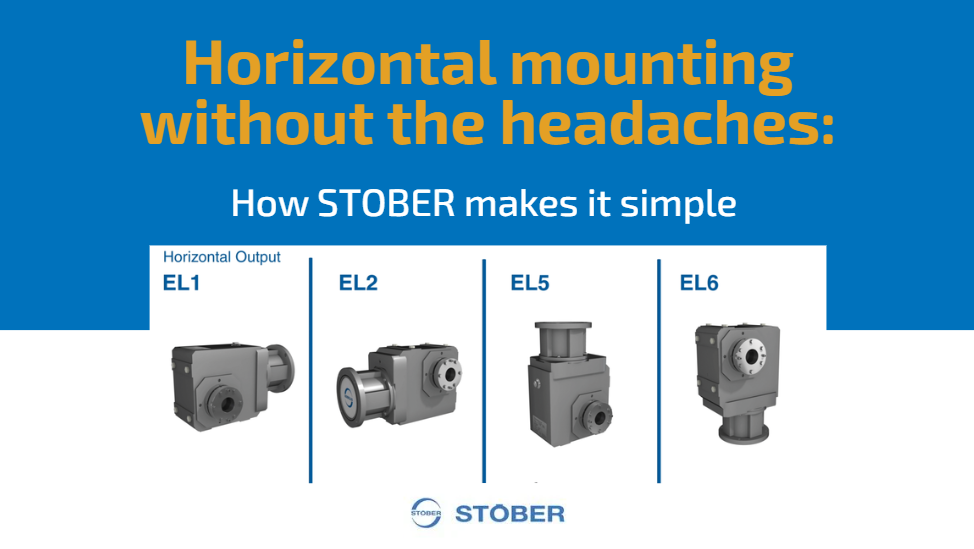

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs