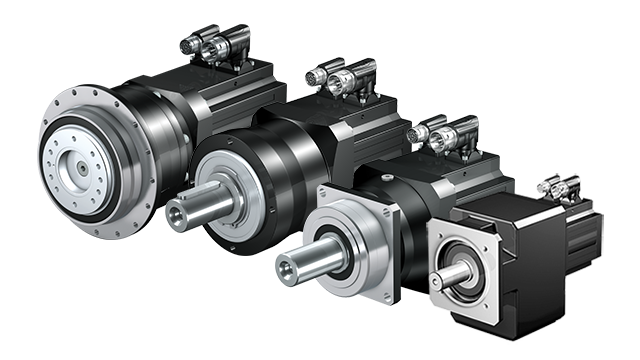

The next time you bite into a delicious pepperoni pizza, think of STOBER! A recent project on a pepperoni slicer for an OEM customer used a servo geared motor to keep pizza production as efficient as possible, speeding up the process while eliminating downtime.

For more than 20 years, Quantum Technical has relied on STOBER to provide gearboxes that are efficient, run cool, and last for years in harsh washdown environments.

“When a customer was looking to run faster than the machine was designed for, STOBER recommended the new servo geared motor,” said John Miller, Service Manager, Quantum Technical Services.

“It was a drop-in replacement for the STOBER/third-party motor combination, required no assembly from motor to gearbox and worked with the existing Rockwell drive while delivering higher speed and more torque,” Miller said. “We are now using this geared motor on all future versions of this machine.”

Food processing has strict cleaning regulations to protect consumers, and the harsh washdown regimens can cause premature failure to many manufacturing parts. However, STOBER products are able to withstand the toughest cleaning processes and have credentials such as IP69K certification. Plus, STOBER’s industry-leading warranty gives customers the peace of mind that the next routine washdown won’t cause downtime.

When it comes to gearboxes and geared motors for the food industry, look no further than STOBER. Click the link below to learn more about STOBER’s solutions for the food industry.

Keyed vs. keyless connections: What’s the difference and why does it matter?

Keyed vs. keyless connections: What’s the difference and why does it matter?  2025 STOBER scholarship winners announced

2025 STOBER scholarship winners announced  Don’t get caught with your plants down – rely on STOBER’s cLEAN System

Don’t get caught with your plants down – rely on STOBER’s cLEAN System  STOBER food-duty gearboxes and geared motors use antimicrobial coating

STOBER food-duty gearboxes and geared motors use antimicrobial coating