STOBER Drives, Inc. is proud to announce that reduced backlash options are now being assembled at our Maysville, Ky. facility. The P, PH (Q), F, K, PKX, PHKX, PK, PH (Q)K, rack & pinion, and geared motors reduced backlash options are all included and will now be available in just days, not months!

The most precise solution on the market, reduced backlash options provide smoothness of motion through precise gearing and offer up to 20 percent higher torque capacity. Reduced backlash is available in all permutations of sizes, housing styles, etc.

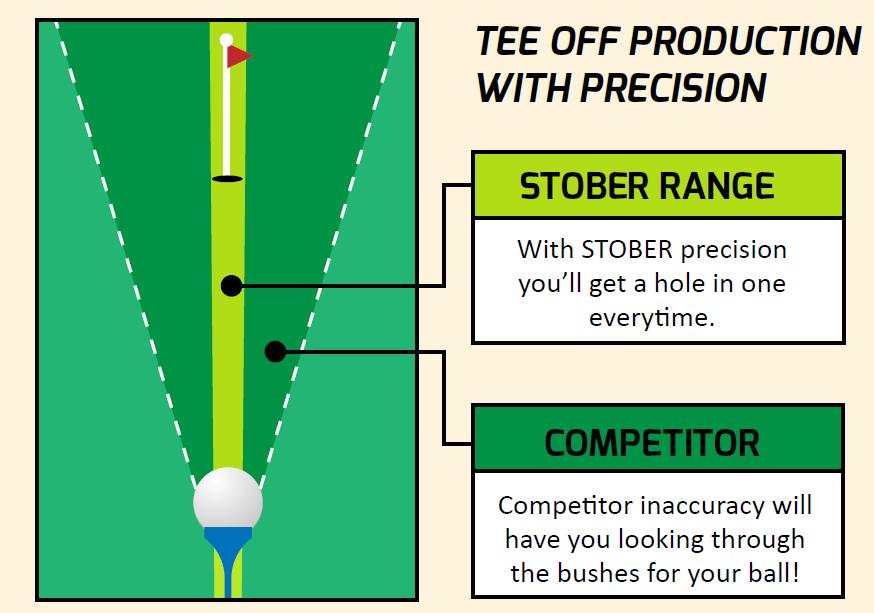

Accuracy provided by reduced backlash is a big deal. To use a golf analogy, imagine having to hit a 160-yard par 3. If a friend uses a regular 6 iron and is off by 0.8 degrees (or 5 arcmin), his ball lands 8.4 inches from the center of the hole. If you use your trusty STOBER 6 iron, your swing is off .02 degrees (or 1 arcmin), your ball is only 1.7 inches from the center of the hole, meaning you’ve just hit a hole in one since the hole is 4.25 inches in diameter! The competitor’s inaccuracy would have you looking for your ball in the trees, but with STOBER precision, you’ll get a hole in one every time!

Uniformity of motion is important to OEMs to ensure production doesn’t become skewed or compromised due to accuracy. For example, label printers run at very high speeds. If the printer becomes even slightly misaligned, the labels won’t be printed in the correct position.

As an added bonus, STOBER has no thermal deviation. Competitor motors generate heat when running, which can cause the need to adjust parameters for thermal growth.

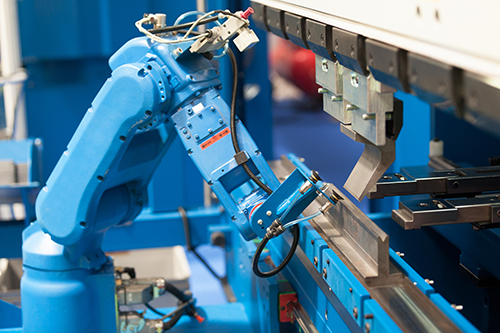

These benefits are ideal in the converting and machine tool industries, including paper mill machinery, folding machines, offset printing, printing trades machinery, milling machines, metal stamping, grinding machines, drilling and boring equipment, power presses, and bending machinery.

Learn more about STOBER’s reduced backlash options by downloading our flyer at the button below, or start building your STOBER gearbox or motor today at configurator.stober.com . For assistance, contact us at (888) 786-2371 or email sales@www.stober.com.

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor

STOBER success: Boosting reliability, efficiency for a major U.S. poultry processor  Selecting gearboxes for robotic & industrial automation systems

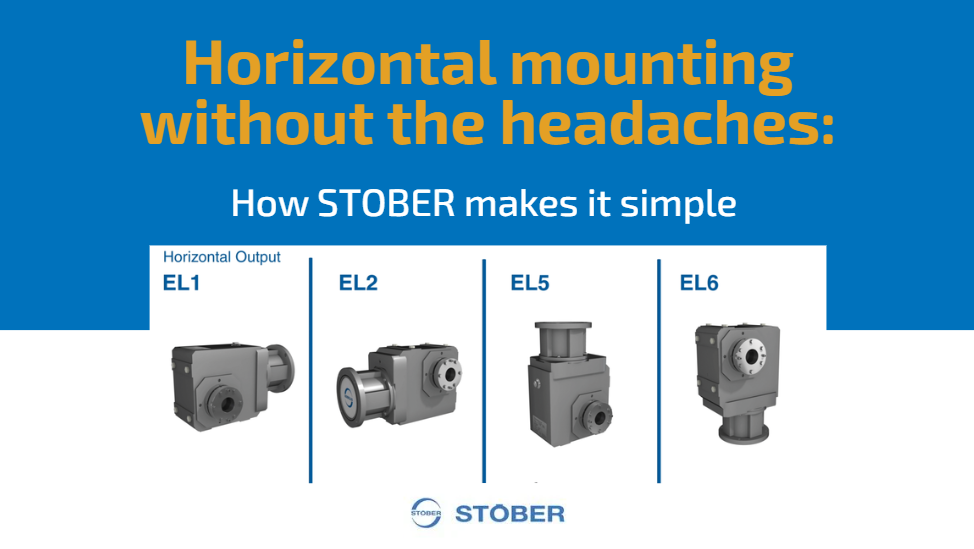

Selecting gearboxes for robotic & industrial automation systems  Horizontal mounting without the headaches: How STOBER makes it simple

Horizontal mounting without the headaches: How STOBER makes it simple  What causes gearbox failure? Key causes & early warning signs

What causes gearbox failure? Key causes & early warning signs