CONVERTING/PRINTING INDUSTRY

Are your gearboxes failing because of high temperatures? “High temperatures are a concern for any gearbox running at least 60% of the time at speeds over 3,000 RPM.” – Machine Design

Applications and Solutions in the Converting/Printing/Web Industry

Printing and converting machines need to be able to run at fast continuous speeds. However, many gearboxes are not able to handle these faster speeds, causing the gearbox to overheat and fail. STOBER gearboxes are capable of handling high continuous speeds without overheating. All gears are heat treated for tooth hardening, preventing cracks because of excessive heat. Our bellows coupling compensate for thermal growth and avoid misalignment of the motor shaft and coupling.

Our engineering expertise is ideal for calibration on converting applications. These applications require high continuous linear speeds in high ambient environments. STOBER has several products that focus on print registration at high speeds. Options include: ATEX explosion proof for alcohol based inks and large hollow bores to allow water and air to pass through the motor for chill, impress rolls.

COMMON CHALLENGES AND PROBLEMS

1. Fast, continuous speeds

2. Excessive heat causing premature failure

3. Limited space for components

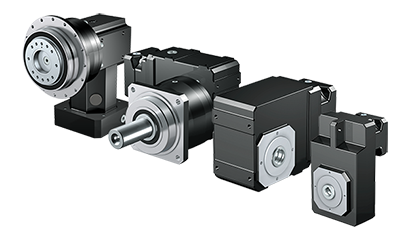

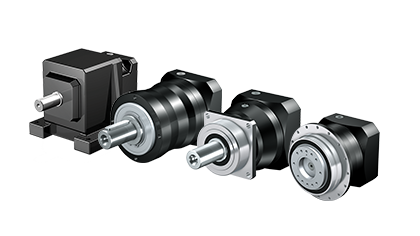

Servo gearboxes for every mounting position

STOBER gearboxes are available in various designs as coaxial or right-angle gearboxes. The latter provide a particularly space-saving design.

High-performance, extremely precise, reliable and outstanding in their particularly wide range of adaptations.

CONFIGURE NOWAll gearboxes have high-quality helical gearing, giving you gearboxes with smooth operation and backlash stability that are second to none.

Learn more

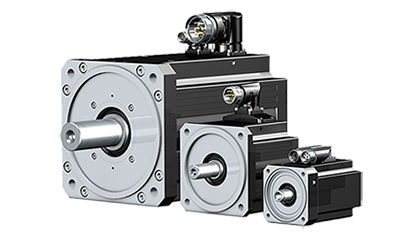

Learn moreSynchronous servo motors with a high power density

For the highest positioning accuracy and dynamics, choose the extremely compact and resilient STOBER EZHD series synchronous servo motors.

- Super-compact

- Maximum torque

- High dynamics