In memory of Mike Noel and Logan Cooper, STOBER is hosting a golf scramble at Kenton Station Golf Course on Saturday, May 18. All proceeds from the event go toward a scholarship fund for Mike’s grandson and Logan’s two sons.

In memory of Mike Noel and Logan Cooper, STOBER is hosting a golf scramble at Kenton Station Golf Course on Saturday, May 18. All proceeds from the event go toward a scholarship fund for Mike’s grandson and Logan’s two sons.

Billie Wallingford, a machinist on our manufacturing team, has worked at STOBER for more than 10 years and will be retiring on April 26.

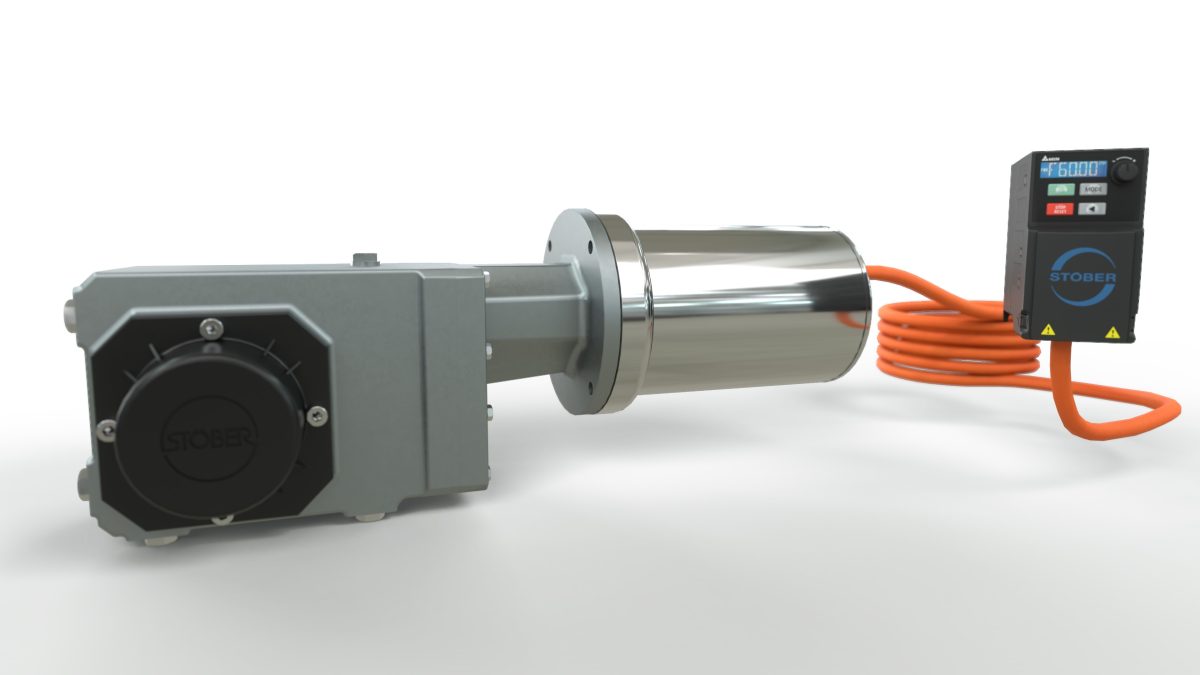

STOBER’s stainless steel & food-duty gearboxes can handle the harshest washdowns and withstand the acidic nature of cheese.

The most compact planetary geared motors on the market just got better. Now with a space-saving design, STOBER’s PH9-12 Generation 4 products feature lower weight, lower mass inertia, higher rigidity, and up to 20 percent more torque. Plus, the reducer interface is 100 percent compatible to the previous generation!

STOBER Drives, Inc. is honored to be named to the 2024 list of Best Places to Work in Kentucky for medium-sized businesses.

STOBER Drives has named Rypli Donahue, Brenna Harris, and Taylor Watts winners of the 2024 Ashley Hurst, Ray Williams and Mike Noel Memorial Scholarship.

STOBER is proud to work with Millard for meat processing equipment that provides sanitary design, equipment reliability, food safety, and more.

STOBER motors and geared motors are flexible in design and compatibility with third-party drives.

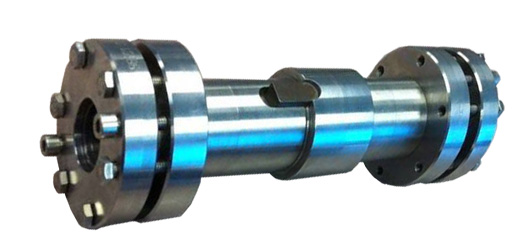

STOBER’s wobble-free bushing is a patented double side bushing system that mounts onto standard cold finished, ground, or stainless shafts.

STOBER’s cLEAN system was created to provide a long-lasting system that improves your plant’s reliability. Durable, efficient, and guaranteed to work in the harshest environments.