STOBER is the world’s leading expert in solutions for the food processing industry, so it’s no surprise that the cLEAN System is the ultimate solution for harsh washdown environments. The top gearbox of choice for 16 of the top 20 food manufacturers in the U.S., STOBER’s stainless steel, food-duty gearboxes and new cLEAN System can handle the most stringent cleaning regiments, including harsh washdowns.

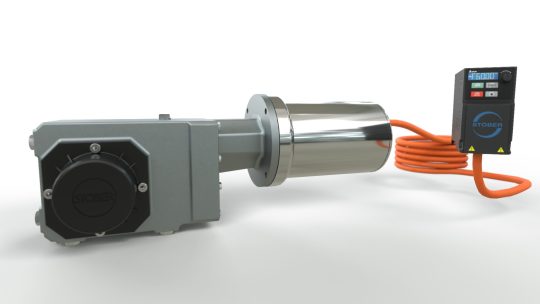

The STOBER cLEAN System has zero weep holes, features double seals on the motor cover and all connection points, and has an o-ring in the cable connection, resulting in a totally enclosed solution that prevents premature failure and saving thousands of dollars in downtime.

The cLEAN Motor has a rounded surface finish with no harborage points. No bacteria can grow on the motor, making it ideal for washdown environments. If additional cleaning beyond the exterior is necessary, the o-ring can be removed for cleaning and the unit can quickly be reassembled. The easy-to-clean design meets EHEDG standards to prevent microbiological problems, prevent ingress or growth of micro-organisms, and ensure long-term durability.

The cLEAN Drive from STOBER supports numerous communication protocols, such as MODBUS, PROFIBUS, EtherCAT, and EtherNet/IP, and is incredibly easy to program and install. The motor quickly mates to the gearbox and the drive can be programmed in just a few minutes. The cLEAN System is compatible with the customer’s communication network of choice and has all the parameters installed.

Experts in the food industry since 1997, STOBER’s dedicated team provides support for the life of the product–from sizing to installation and beyond. The entire cLEAN System (stainless steel gearbox and motor, Ecolab certified cable, and preprogrammed drive) is backed by a three-year warranty. Built and shipped in less than one week from Maysville, Ky., the cLEAN System is ready to take on your harsh washdown challenges!

Contact sales@www.stober.com, or call (888) 786-2371 for more information.

Meet the engineers behind STOBER innovation

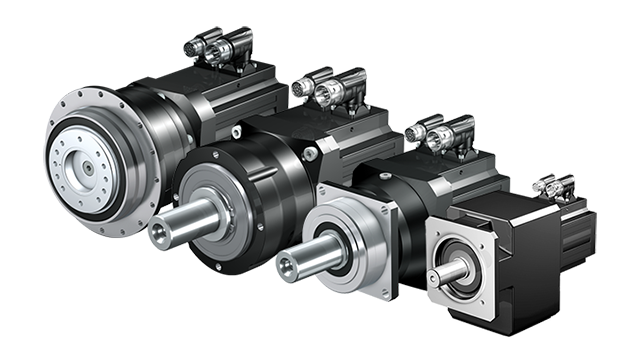

Meet the engineers behind STOBER innovation  Understanding the different types of geared motors

Understanding the different types of geared motors  Synchronous vs. asynchronous motors: The foundation of servo technology

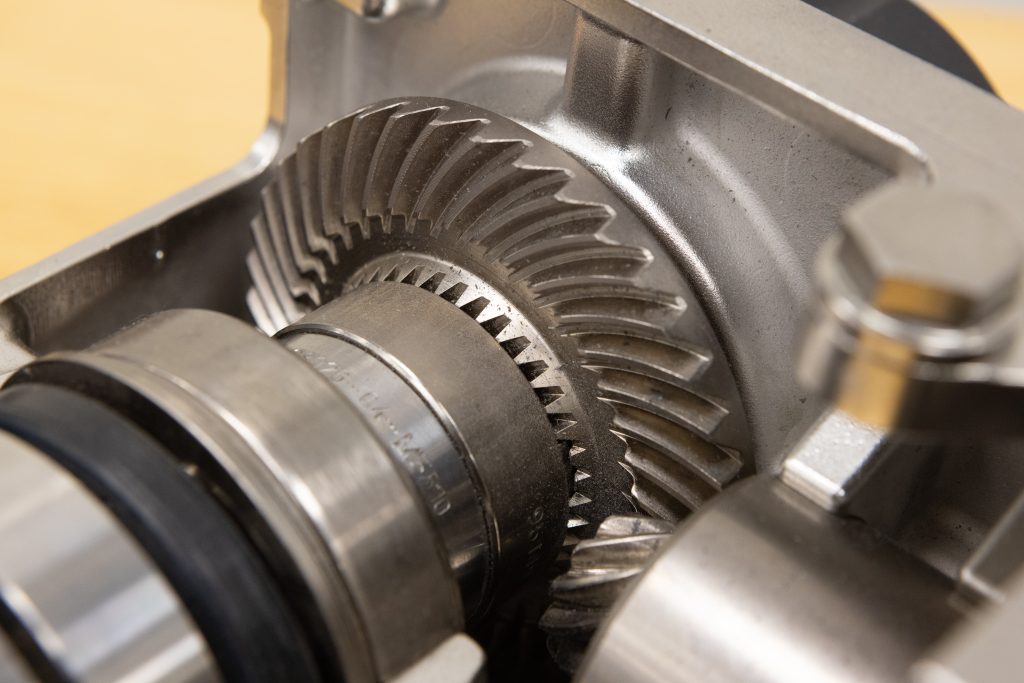

Synchronous vs. asynchronous motors: The foundation of servo technology  How to calculate gear reduction: Formula, examples & applications

How to calculate gear reduction: Formula, examples & applications