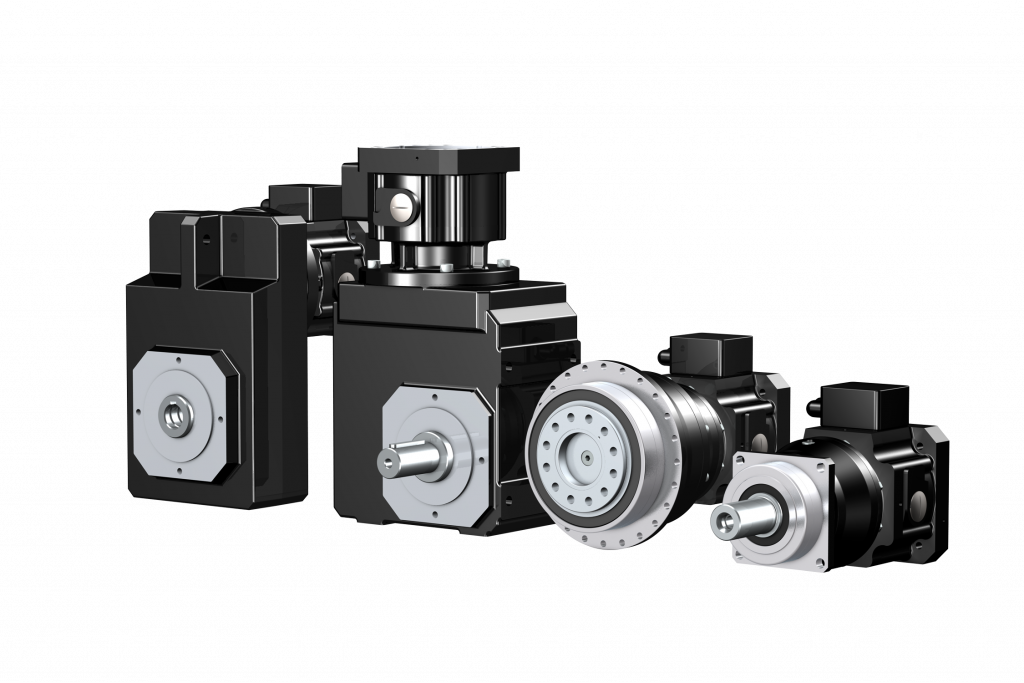

Did you know STOBER’s servo gearboxes can be paired with ServoStop, a revolutionary integrated safety brake? It’s ideal for vertical applications, provides redundant braking, and prevents slipping or falls even when the motor is removed.

When machinery incorporates vertical axes, common in material handling for robotics or machine tool industries, providing safe braking can be a challenge. These situations can be caused by a power being cut off to the drive due to a problem in the machine controller, power failure, or brake failure in the motor. ServoStop safety brake can brake at full speed, prevent accidental sliding or falling of vertical axes with gravity load, and provide reliable braking during emergencies or power failures.

Originally designed for a safety application where redundant braking is needed, ServoStop provides dynamic braking during power failures or emergency stops in hazardous situations. It’s integrated into the gearbox and prevents accidental sliding or falling of vertical axis. The servo motor can be dismounted, even with a load and even with the brake engaged.

ServoStop is backlash-free, smooth-running, and offers frictional shaft to hub for high torque all within a compact design for low inertia. Plus, ServoStop can be mounted on almost all common servo motors, meaning it can universally fit applications in factories everywhere. ServoStop’s plug-in coupling allows for simple motor removal, no matter what position the braked axis is in, and prevents the gravity-affected axes from sinking or crashing.

Providing safe braking can be difficult as well as dangerous, especially when machinery incorporates vertical axes– which is common in material handling for robotics or machine tools industries. Let STOBER show you how safe integrated braking can be.

Learn more about STOBER’s ServoStop options by clicking the link below or contact us at (888) 786-2371 or email sales@www.stober.com.

What is a planetary gearbox and how does it work?

What is a planetary gearbox and how does it work?  Keyed vs. keyless connections: What’s the difference and why does it matter?

Keyed vs. keyless connections: What’s the difference and why does it matter?  2025 STOBER scholarship winners announced

2025 STOBER scholarship winners announced  Don’t get caught with your plants down – rely on STOBER’s cLEAN System

Don’t get caught with your plants down – rely on STOBER’s cLEAN System